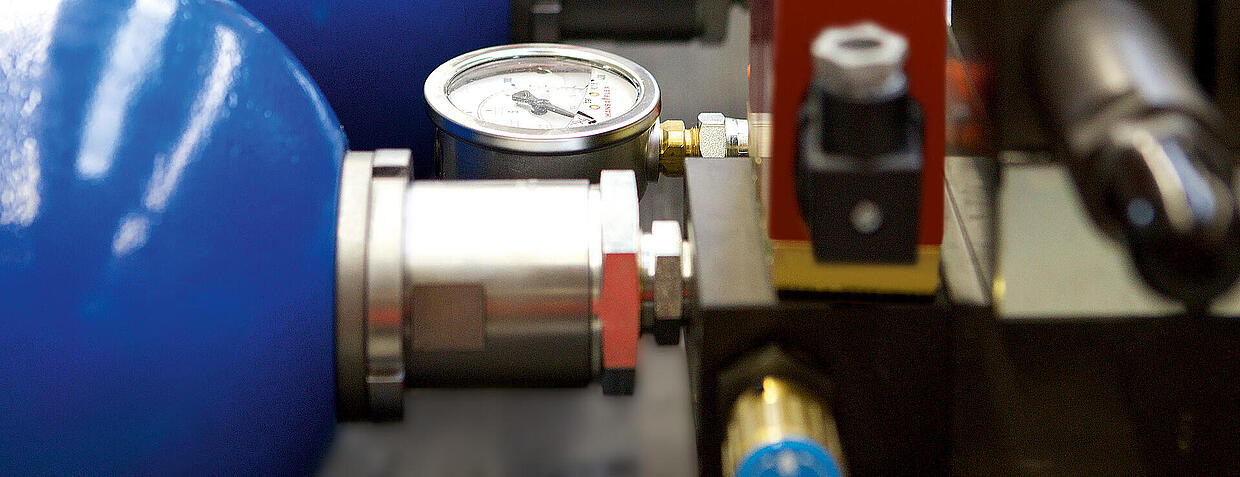

Servicing and repair of pressure accumulators

Services and products for servicing hydraulic accumulators

We recommend that an identical hydraulic accumulator is always kept on site as a replacement. By doing this you can avoid long standstills. You can find a large selection of pressure accumulators in the HANSA‑FLEX online shop. Other accumulators can be su

Quickly back in working order

The fluid experts are qualified as officially authorised persons for pressure equipment. They are able to support you in all the work involved in replacing defective bladders, diaphragms and seals.

- Support in the preparation of risk assessments

- Replacement and repair of defective pressure accumulators

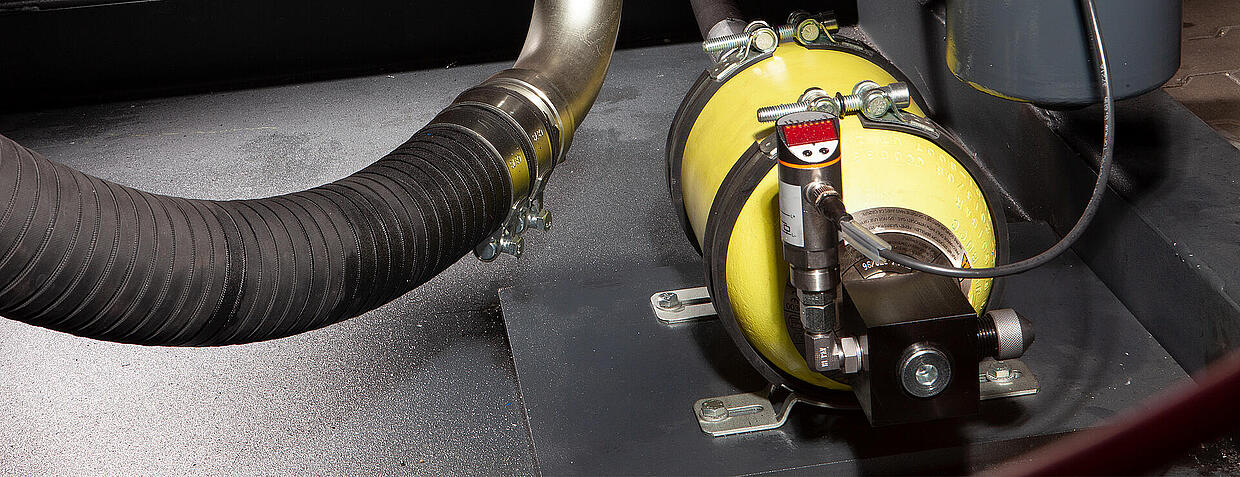

- Nitrogen filling

- Checking gas pressure and oil valve on base

- Fault finding after sudden failure

Repair kits for bladder accumulators

The HANSA‑FLEX online shop has a selection of repair kits for the renovation of bladder accumulators.

- Replacement bladder, gas valve with protective cap and seal kit

- For standard NBR bladders

- Including repair instructions

HANSA‑FLEX’s servicing teams offer all these advantages

With HANSA‑FLEX, the leading experts in fluid technology, you always have an experienced partner at your side.

-

Qualified specialist personnel

All work on hydraulic accumulators is carried out by officially authorised persons for pressure equipment.

-

No compromise on safety

All the requirements of the German Industrial Health and Safety Act (BetrSichV) are observed.

-

Comprehensive support

We carry out all the tasks such as gas charging or the replacement of the accumulator bladder.

-

Advice from experts

We support you in the preparation of risk assessments and your inspection and testing plans.

All-round carefree service from the fluid specialists

HANSA‑FLEX is your competent partner for all the tasks required for the installation and operation of pressure accumulators.

- Advice on the selection and design of pressure accumulators

- Sale of pressure accumulators, accessories and repair kits [Link to landing page “Pressure accumulators”]

- Installation of pressure accumulators

- Inspection of hydraulic accumulators [Link to landing page “Inspection of pressure accumulators”] by officially authorised persons

- Training and seminars [Link to landing page “Training and seminars“] on the servicing and operation of pressure accumulators

What to consider when replacing hydraulic accumulators

Performing the work

The servicing and inspection of pressure accumulators must be performed by an officially authorised person in accordance with the German Industrial Health and Safety Act. An officially authorised person has the required specialist knowledge about servicing and inspection of operational material such as pressure equipment. This knowledge comes from the person’s education and training and professional experience. An officially authorised person must also have passed the relevant examination at the end of the training. Their function within the company does not become effective until they have been named as an officially authorised person by their engineering or operations manager. If you ask us to maintain your equipment, you can count on all the work carried out by HANSA‑FLEX on hydraulic accumulators been done by officially authorised persons for pressure equipment.

Replacement with an identical pressure accumulator

Replacing a hydraulic accumulator on a machine or plant with an identical pressure accumulator does not require a new approval. However, the replacement must be recorded in the factory documentation. The time to the first recurring inspection starts from when the new hydraulic accumulator is brought into use and continues at the specified intervals. A properly carried out seal replacement is also not a safety-relevant modification of the hydraulic accumulator. A new initial inspection by an Approved Inspection Body (ZÜS) is therefore not required.

New place of use

If the pressure accumulator has a new place of use, for example, is installed in another machine, then an inspection before being brought into use is not required provided certain preconditions are fulfilled:

- An inspection has been carried out elsewhere before being brought into use in the new location

- No new method of operation

- Connections and equipment are otherwise unchanged

- No special requirements at the new place of use

Storage of hydraulic accumulators

Having a suitable replacement to hand is always a good idea. This also applies to pressure accumulators. The following points must be observed for a stored accumulator:

- Corrosion or elastomer ageing can take place in storage.

- A visual inspection normally reveals any damage.

- The inspection interval is not extended during storage.

Our experts recommend

When having your pressure accumulator serviced, you should ensure that your hydraulic accumulator is always returned to you after maintenance at the manufacturer or service centre. This ensures that you have an exact replacement on hand should the currently installed pressure accumulator fail. HANSA‑FLEX carries out the repair directly for you on site. This saves you time and the cost of shipping. Any work performed on pressure accumulators must comply with the requirements of Section 14 (5) of the German Industrial Health and Safety Act (BetrSichV). You should also be aware that a recurring inspection by the appropriate specialist personnel must be carried out after a repair such as the replacement of a bladder, diaphragm or seal.

Expert advice

A defective bladder indicates there was too much or too little gas pressure in the hydraulic system. The HANSA‑FLEX specialists are always pleased to advise you.

These topics may also be of interest to you

Inspection of your pressure accumulator by an officially authorised person

The fluid experts from HANSA‑FLEX are officially authorised persons for pressure equipment. They carry out external visual inspections and provide inspection reports.

Gas-filled pressure accumulators from HANSA‑FLEX

The HANSA‑FLEX range includes numerous high-quality diaphragm and bladder accumulators for various designs from renowned manufacturers.

Prevent wear

The cleanliness of the hydraulic fluid affects the service life of components. Oil cleaning and regular analyses help you avoid system breakdowns.

Mexico

Mexico