Pressure accumulator inspections are obligatory

Inspection of hydraulic accumulators by officially authorised persons

At HANSA‑FLEX, a large number of employees throughout Germany are qualified as competent persons for pressure equipment. As fluid experts, they also have extensive experience with pressure accumulators, provide expert advice on all questions and are always ready to help you. HANSA‑FLEX offers its customers the following services:

- Performance of recurring inspections

- Support in the preparation of risk assessments

- Documentation of inspection results in accordance with BetrSichV

HANSA‑FLEX services offer all these advantages

With HANSA‑FLEX, the leading experts in fluid technology, you always have an experienced partner in pressure equipment technology at your side.

-

Qualified specialist personnel

Inspections performed by officially authorised persons (TRBS 1203 No. 3.2 and No. 2).

-

No compromise on safety

Ensure compliance with all the requirements of the German Industrial Safety Act.

-

Comprehensive support

We support you in the preparation of risk assessments and your inspection and testing plans.

-

Advice from experts

Our experts advise you on the choice, design and operation of your pressure accumulator system.

Classification of pressure accumulators

The scope of the inspections depends on the category of the pressure accumulator. Hydraulic accumulators are divided into systems that need to be monitored and systems that do not need to be monitored in accordance with the European Pressure Equipment Dir

Large pressure accumulators with an operating pressure of more than 1 bar

Alle Hydrospeicher mit einem Gasvolumen von mehr als 10 l gelten als überwachungsbedürftige Anlagen und unterliegen bei der Inbetriebnahme besonderen Prüfpflichten sowie regelmäßigen Überprüfungen gemäß der Betriebssicherheitsverordnung (BetrSichV). Die Abnahme nach der Installation sowie alle wiederkehrenden Prüfungen an diesen Druckspeichern dürfen nur von Fachexperten einer zugelassenen Überwachungsstelle (ZÜS) oder einem von diesem beauftragten Unternehmen wie dem TÜV oder der DEKRA durchgeführt werden. Die Fristen der wiederkehrenden Prüfungen erfolgen auf der Grundlage der sicherheitstechnischen Bewertung und sind spätestens 6 Monate nach Inbetriebnahme festzulegen und durch eine ZÜS überprüfen zu lassen.

Medium-pressure accumulators with an operating pressure of not more than 1 bar

Hydropneumatische Druckspeicher mit einem Gasvolumen zwischen 1 und 10 l müssen sowohl vor der Inbetriebnahme als auch in wiederkehrenden Intervallen geprüft werden. Alle Prüfungen müssen von einer befähigten Person für Gefährdungen durch Druck (TRBS 1203 Nr. 3.2) durchgeführt werden.

Die Prüffristen legt der Betreiber anhand der vom Hersteller bereitgestellten Informationen, der Betriebsweise sowie eigener Erfahrungswerte selbstständig fest. Die in der BetrSichV angegebenen Prüfintervalle dienen nur zur Orientierung.

Small pressure accumulators with an operating pressure of not more than 0.5 bar

Druckspeicher mit einem Gasvolumen zwischen 0,1 l und 1 l Volumen werden als nicht überwachungsbedürftige Druckanlagen eingestuft und gelten als Arbeitsmittel im Sinne der BetrSichV.

Eine Prüfung vor Inbetriebnahme ist nicht vorgeschrieben, dennoch muss der Betreiber gemäß der erstellten Gefährdungsbeurteilung entsprechende Schutzmaßnahmen festlegen. Dazu zählt auch die Durchführung einer wiederkehrenden Prüfung nach §10 der BetrSichV durch eine befähigte Person für Gefährdungen durch Druck nach TRBS 1203 Nr. 2.

Expert advice

A defective bladder indicates there was too much or too little gas pressure in the hydraulic system. The HANSA‑FLEX specialists are always pleased to advise you.

Inspection intervals for pressure accumulator systems

The inspection intervals for systems that require to be monitored are defined in the German Industrial Safety Act (BetrSichV). The definitive parameter for this classification is the permissible operating pressure safeguarded by the safety equipment.

Process and scope of pressure accumulator inspections

Inspection before bringing into first use

Vor der Inbetriebnahme eines Druckspeichers wird neben der technischen Funktionsfähigkeit überprüft, ob eine CE-Kennzeichnung, Betriebsanleitung, die Kennnummer der benannten Stelle und die notwendigen Sicherheitsausrüstungen vorhanden sind. Je nach Kategorie des Druckspeichers wird die Prüfung von unterschiedlichen Stellen durchgeführt:

- Über 10 l Gasvolumen: Zugelassene Überwachungsstelle (ZÜS)

- Bis zu 10 l Gasvolumen: Befähigte Person für Gefährdungen durch Druck nach TRBS 1203 Nr. 3.2

- Unter 1 l Gasvolumen: Befähigte Person nach TRBS 1203 Nr. 2

Recurring inspections

Im Rahmen der wiederkehrenden Prüfungen wird sichergestellt, dass CE-Kennzeichnung und Betriebsanleitung vorliegen sowie die Ausrüstung mit Sicherheitsfunktion noch vorhanden, funktionsfähig und richtig eingestellt ist. Zudem wird überprüft, ob die Voraussetzungen für das nächste Prüfintervall noch korrekt sind. Folgende Unterlagen sollten Sie unbedingt bereithalten:

- Bedienungsanleitung und Gefährdungsbeurteilung

- Alle Unterlagen des Herstellers des Hydrospeichers

- Die betrieblichen Unterlagen der Inbetriebnahmeprüfung

Unscheduled inspections in the course of servicing and maintenance

Änderung des Betriebsdrucks

Eine Änderung des Betriebsdrucks bei einem Druckspeicher beeinflusst stets die Sicherheit der gesamten Anlage oder Maschine. Daher ist im Zuge einer Anpassung des Betriebsdrucks erneut eine Prüfung vor Inbetriebnahme erforderlich. Diese muss je nach Kategorie des Hydrospeichers von einer befähigten Person oder der zulässigen Überwachungsstelle (ZÜS) durchgeführt werden.

Auswechseln baugleicher Druckspeicher

Beim Auswechseln eines Hydrospeichers in einer Maschine oder Anlage gegen einen baugleichen Druckspeicher ist keine Neuabnahme durch eine zugelassenen Überwachungsstelle (ZÜS) oder eine befähigte Person erforderlich. Die Frist bis zur ersten wiederkehrenden Prüfung läuft ab dem Zeitpunkt der Inbetriebnahme des neuen Hydrospeichers gemäß den bereits festgelegten Prüfintervallen.

Neuer Aufstellungsort

Wird der Aufstellungsort des Druckspeichers beispielsweise beim Einbau in eine andere Maschine verändert, ist eine Prüfung vor Inbetriebnahme nur unter bestimmten Voraussetzungen nicht erforderlich:

- Bereits andernorts durchgeführte Prüfung vor Inbetriebnahme

- Keine neue Betriebsweise

- Unveränderte Anschlussverhältnisse sowie Ausrüstung

- Keine besonderen Anforderungen an Aufstellungsort

Instandhaltungsarbeiten

Nach Instandsetzungsarbeiten wie beispielsweise dem Blasen-, Membran- oder Dichtungswechsel muss eine wiederkehrende Prüfung des Hydrospeichers durch das entsprechende Fachpersonal erfolgen. Diese Regelung gilt für alle Druckgeräte ab 1 l Gasvolumen.

Lagerung von Hydrospeichern

Bei der Lagerung von Druckspeichern können Schäden wie Korrosion an der Sicherheitsausrüstung oder Alterungserscheinungen des Elastomers auftreten. Daher sollte vor dem Einbau der gesamte Hydrospeicher durch einen Fachmann in Augenschein genommen werden. Zudem ist bei der Lagerung wichtig zu wissen, dass sich während der Lagerzeit die Prüffrist nicht verlängert.

All-round carefree service from the fluid specialists

HANSA‑FLEX is your competent partner for all the tasks required for the installation and operation of pressure accumulators.

- Advice on the selection and design of pressure accumulators

- Sales of pressure accumulators, accessories and repair kits

- Installation of pressure accumulators

- Maintenance and repair by officially authorised persons

- Training and seminars on the servicing and operation of pressure accumulators

These topics may also be of interest to you

Repair and overhaul of pressure accumulator systems

HANSA‑FLEX Industrial Service supports you with all servicing and maintenance work on your pressure accumulator systems, including nitrogen filling or their replacement.

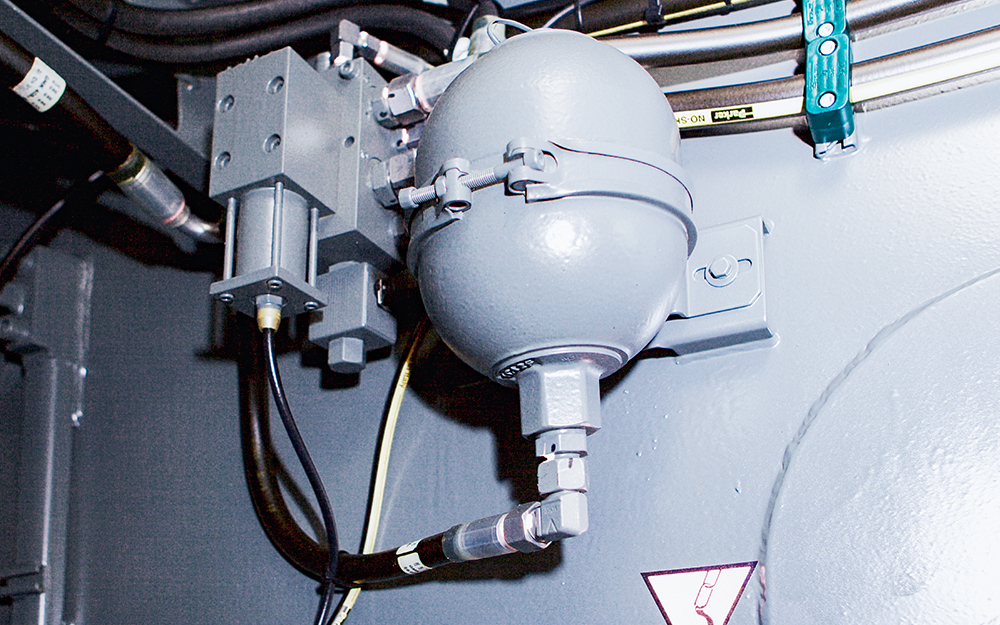

Gas-filled pressure accumulators from HANSA‑FLEX

The HANSA‑FLEX range includes numerous high-quality diaphragm and bladder accumulators of various designs from renowned manufacturers.

Prevent wear

The cleanliness of the hydraulic fluid affects the service life of components. Oil cleaning and regular analyses help you avoid system breakdowns.