Avoid risks, keep machines maintained

Challenges and advantages of preventive maintenance

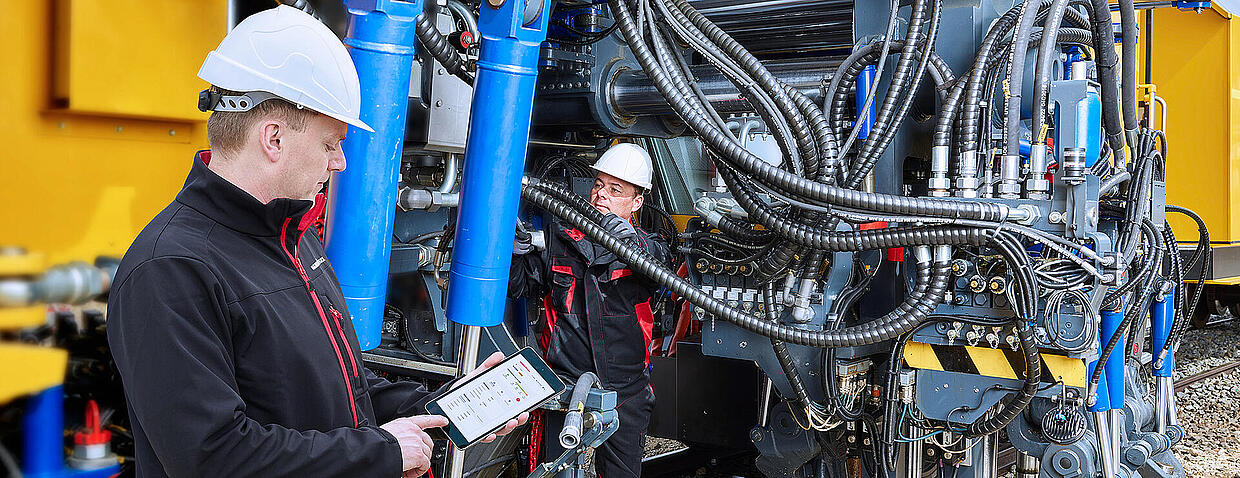

Whether safety at work, system availability or cost savings, conservation of natural resources, energy efficiency or digitalisation: the requirements for maintenance today are as numerous as they are complex. System maintenance increasingly relies on proactive and forward-looking strategies to ensure as few malfunctions as possible in production processes. Systematically planning servicing and inspections as part of preventive maintenance can reduce the number of unplanned machine breakdowns and make an important contribution to overall success on the production floor.

Preventive maintenance of hydraulic and other components

The special characteristics of hydraulic components such as hose lines or pressure accumulators and the associated legally prescribed inspection and replacement intervals applying to them mean they are prime examples of equipment requiring professionally designed preventive maintenance plans.

Benefit from the tools and know-how of HANSA‑FLEX hydraulics specialists in the conception, implementation and the legally compliant, practical implementation of your individual maintenance strategy. Your machines will operate more reliably for longer and your team will have more time for dealing with unplanned events.

Operate systems and work equipment safely and in compliance with the law

Hydraulic hose lines have a limited service life and must be professionally inspected at regular intervals to ensure your machines and systems operate safely and in compliance with the law.

The inspections must take place in accordance with the legally prescribed risk assessment in each case and be properly documented. We support you from A to Z in fulfilling these obligations with 360° hose management. This leaves you in a better position to concentrate on your core business.

Hose management HANSA‑FLEX style

Professional hose management consists of several essential elements. Find out everything about our versatile hose coding system, unique hose management software and the services available from our specialist installation technicians.

Simply unique: hose identification with X-CODE

A coding system tried and tested millions of times. One code contains all the information. Attached as a Tip Tag marker, self-adhesive label or wraparound ID plate, with QR code and RFID.

X-CODE Manager, the easy-to-use hose management software

Efficient software for all system maintainers. Benefit from the best overview of your hose lines, machines and servicing dates.

Support at a fixed price: hose management service package

Planning certainty for a fixed daily flat rate. Discover our service packages for digitalisation, data maintenance, installation, inspections on site, and more.

Keep on the safe side with HANSA‑FLEX

Experienced specialists qualified as officially authorised persons support you with the inspection of your systems and work equipment in accordance with the currently applicable legal requirements. Benefit from our expertise and experience!

We inspect the following for you:

- Hydraulic hose lines in accordance with DGUV and BetrSichV

- Industrial hose lines in accordance with TRBS 1201

- Pressure accumulators in accordance with the Pressure Equipment Directive (PED) and BetrSichV

- Lifting platforms and loading bridges in accordance with DGUV and BetrSichV

Inspections of everything from hose lines to lifting platforms

Inspection of hydraulic hose lines

We perform the legally prescribed inspections of your hydraulic hose lines in accordance with BetrSichV / DGUV for you and take care of the legally compliant documentation of the results. Inspections are carried out directly on site for you by officially authorised persons for inspecting hydraulic line equipment. Every inspection can be booked as an individual service or as part of our hose management package within our 360° hose management service.

Inspection of pressure accumulators

Pressure or hydraulic accumulators are work equipment that can give rise to special risks. As pressurised containers, they are among the systems that need to be monitored in accordance with product safety legislation and are classified into one of four categories in accordance with the Pressure Equipment Directive (PED). We can perform the inspections required before hydraulic accumulators Category I are brought into use and the recurring inspections of hydraulic accumulators Categories I & II. An officially authorised person for pressure equipment with additional qualifications performs these inspections for you.

Inspection of industrial hose lines

We inspect all types of hose lines for chemicals, foodstuff, pharmaceuticals and other media. Inspections are carried out in our specialist centres for hose technology inspection or directly on site for you. For the mobile inspection service, an officially authorised person for inspections in accordance with TRBS 1203 in a fully equipped inspection vehicle performs all the prescribed inspections. Inspection certificates, identification label strips and inspection stickers can be produced on the vehicle and immediately applied.

Inspection of lifting platforms

We perform regular recurring inspections of lifting platforms and loading bridges in accordance with European standards DIN EN 1493, DIN EN 1494 and DIN EN 1495 for you. We also prepare all the legally required documentation of the inspections in accordance with of the German Industrial Safety Act (BetrSichV). Our service technicians are certified experts in lifting platforms in accordance with DGUV Rule 308-002 governing the inspection of lifting platforms. They perform the visual inspections and function tests in accordance with the requirements of GUV Rule R-500 “Operation of work equipment”.

You may also be interested in this

HANSA‑FLEX Fluid Service reveals the secrets of your oil

Many machine breakdowns can be traced to contaminants in hydraulic oil. Professional oil analysis by HANSA‑FLEX reveals the possible causes of this in good time.

Fit in theory and in practice: seminars for system maintainers

The International Hydraulics Academy (IHA) is Europe’s renowned provider of specialist hydraulics seminars and recognised certifications.

We bring your machines back to life again

Specialist service technicians support you on site with the repair and refurbishment of your hydraulic systems.

Mexico

Mexico