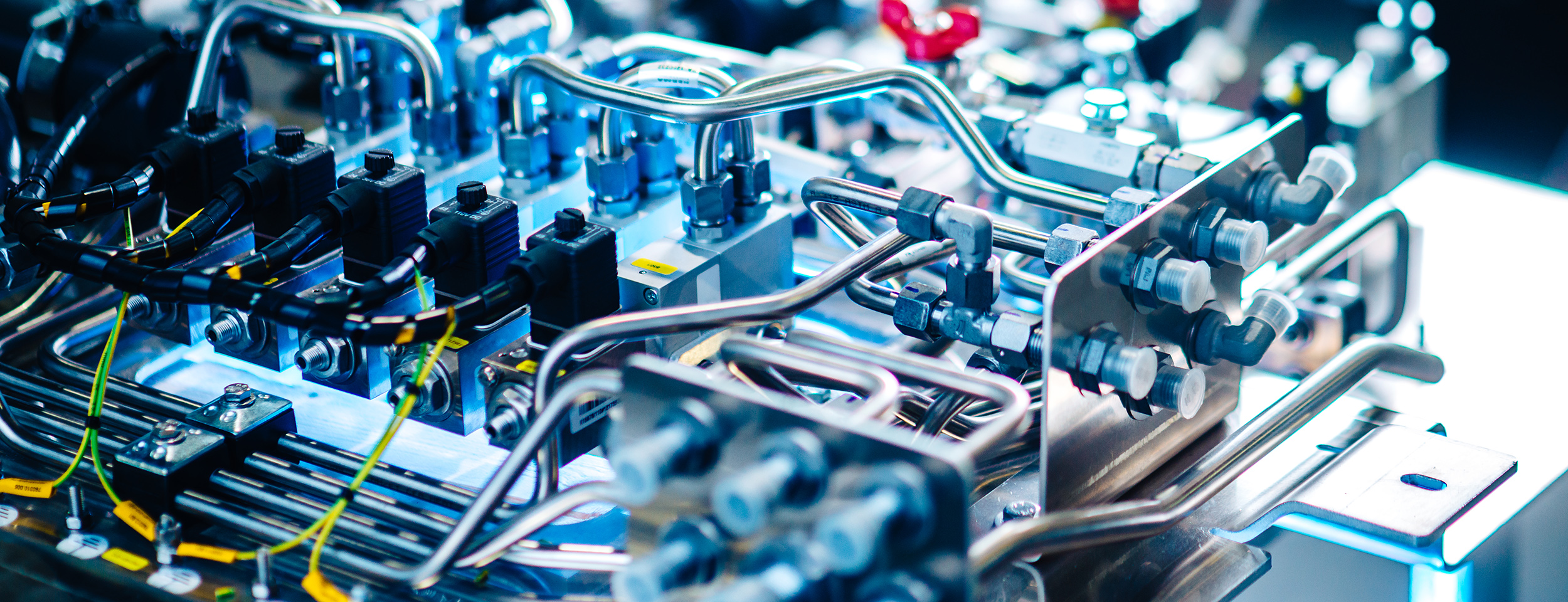

Bent pipes for fluid technology from HANSA‑FLEX

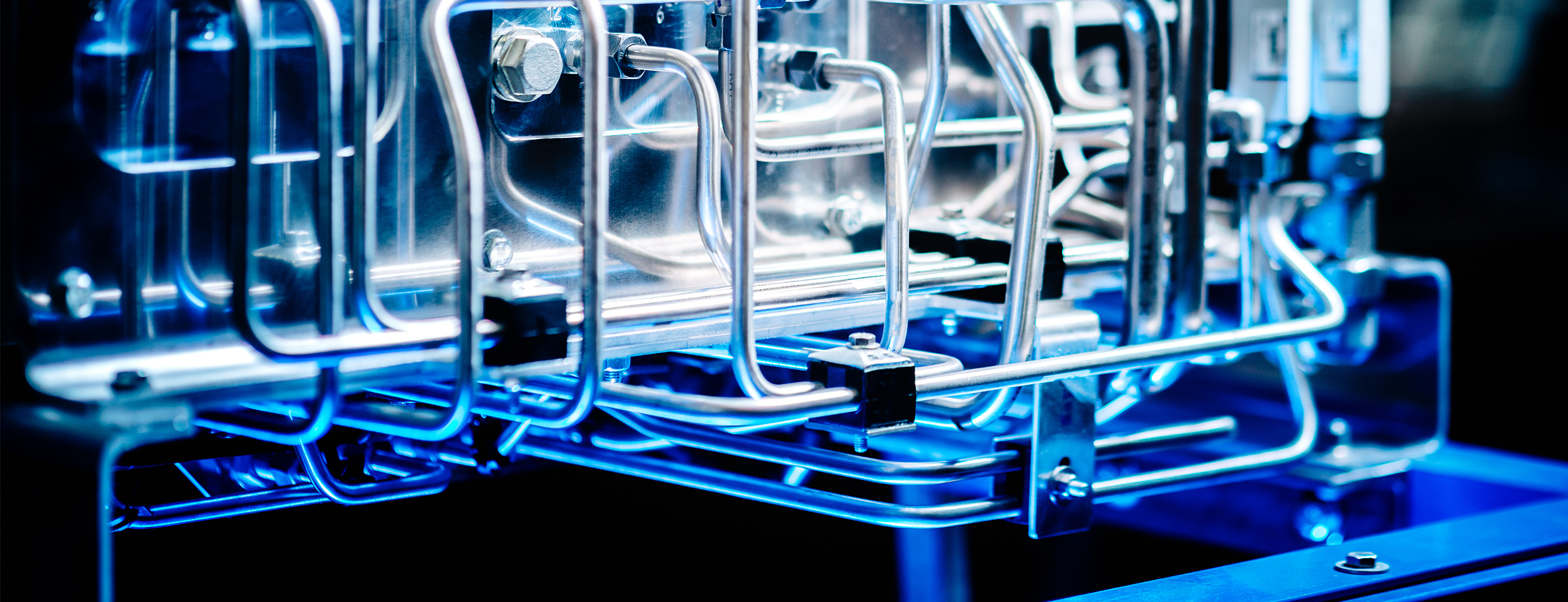

Bent pipes manufactured with absolute precision

Two short videos give interesting insights into the manufacturing processes in the HANSA‑FLEX pipe bending centre in Schönebeck and the special fitting manufacturing facility in Weixdorf.

Bent pipes and special fittings

HANSA‑FLEX designs and manufactures bent pipes and special fittings with the highest precision, using state-of-the-art technologies and in first class quality.

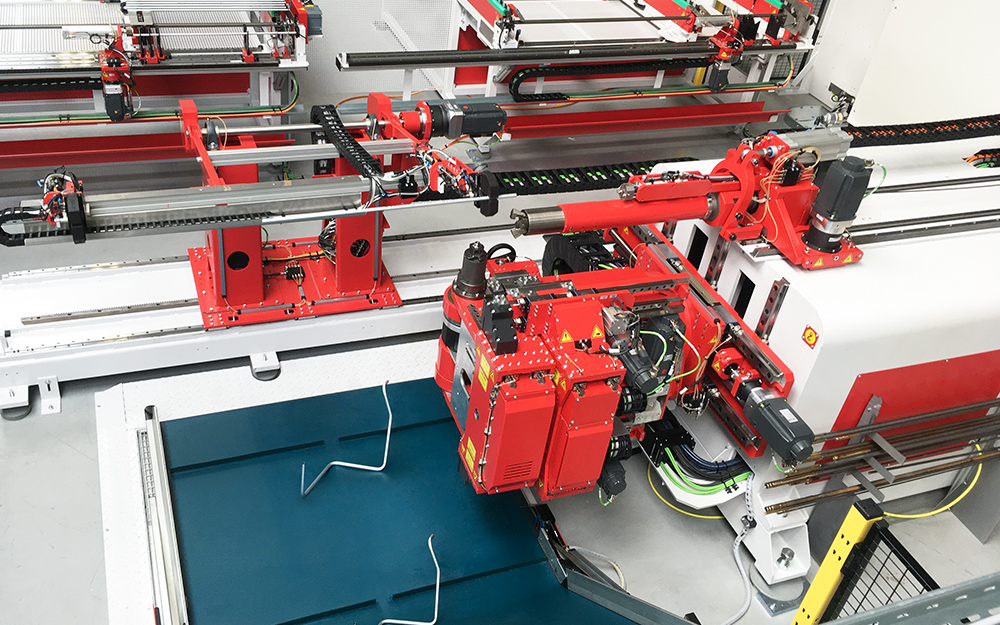

HANSA‑FLEX high-tech pipe bending cell

The high-tech pipe bending cell operatives are completely familiar with all the necessary manufacturing steps from feeding in the cut-to-length pipe to the correct storage of the bent pipe.

Dependable competence and quality

HANSA‑FLEX makes use of synergies between the specialist departments to meet the highest customer expectations in the fabrication of pipes and special fittings.

The pipe bending centre and branches work hand-in-hand

The experts in the HANSA‑FLEX pipe bending centre have the necessary skills and knowledge of pipe bending and fluid technology to master the most complex challenges. They work closely with the specialists from the HANSA‑FLEX branches. You can expect the best possible advice and an optimum path from conception to manufacture. On request, HANSA‑FLEX is happy to manufacture ready-to-install pipe sets and deliver them Just-In-Time directly to the customer’s installation site, so that the entire process after pipe bending runs smoothly.

Checking the shape of pipe bends

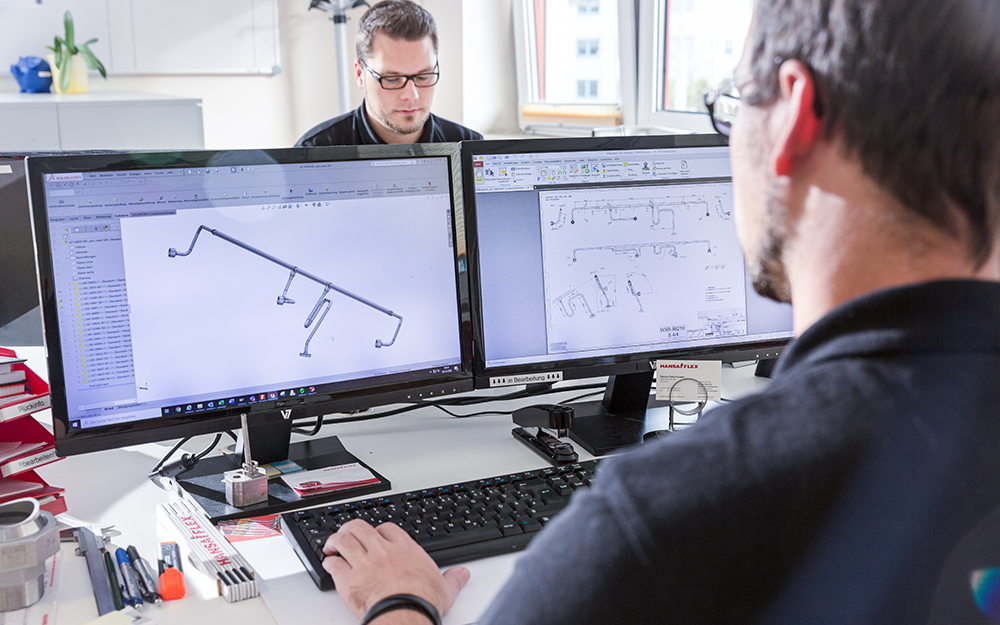

The bending experts at HANSA‑FLEX determine all the data required for the bent pipe from the computer simulation. If the simulation shows that the degree of ovalisation in the bend area exceeds the 10 % limit applied in hydraulics, then an internal mandrel is used during bending to prevent the pipe cross section from narrowing.

Reducing the ovalisation reduces turbulence in the pipe system and increases efficiency.

Well-equipped production floor

To meet the diverse requirements for pipe geometry needs many more than one type of machine. The extensive range of machines in the pipe bending centre allows HANSA‑FLEX to perform a wide variety of bending tasks and produce the highest quality results.

HANSA‑FLEX continually acquires new machines to ensure not only the highest precision but also maximum flexibility on the production floor. Around 20 further CNC machines augment a fully automated bending cell.

HANSA‑FLEX bent pipes fit your requirements exactly

HANSA‑FLEX always strives to fulfil every individual customer requirement to the best possible standard. The production floor for special pipes and fittings is equipped to offer customers a wide choice of possible ways of implementing any project.

-

Very high accuracy

Manufacturing accuracies of up to 0.3 mm, depending on the total length of the product.

-

Manufacturing exactly to size

Pipes up to 6,000 mm long and 4.00 to 101.60 mm diameter.

-

Manufacturing flexibility

A large selection of tools to create the perfect radius for your requirements.

-

All available materials

HANSA‑FLEX bends precision steel pipes from stainless steel or copper

Feasibility check and custom-made components

HANSA‑FLEX manufactures bent pipes, special pipes and special fittings in a variety of practical forms quickly, precisely and in the proven quality suitable for OEM suppliers or as replacement parts.

Bending parameters defined using computer simulations

All enquiries for bent pipes are first subjected to a HANSA‑FLEX feasibility check. This simulation is done with visualisation software. The software considers all parameters such as bend length, stretching and springback. From these values, it calculates the precise sawn length of pipe that will result in a ready-to-install bent pipe after bending. A suitable CNC bending machine makes the bent pipe using the data from the simulation. The manufactured prototype is then checked using a measuring arm and compared to the master data. If all the dimensions agree, the feasibility check is passed under the HANSA‑FLEX technician gives the green light for production.

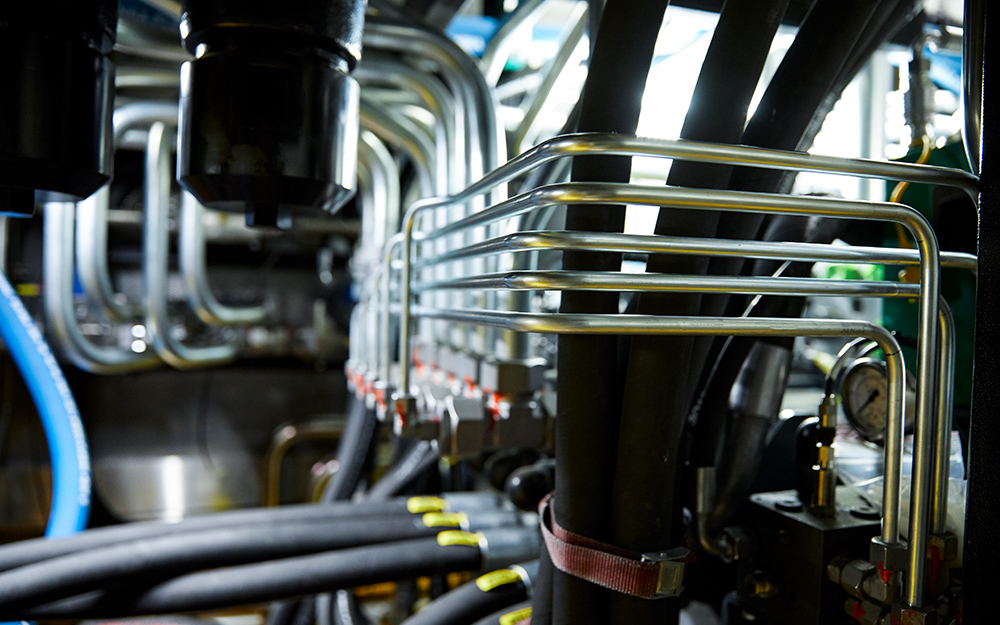

Special pipes and fittings from Weixdorf

Individually manufactured pipelines and fittings are often required in fluid technology. HANSA‑FLEX set up a special manufacturing centre for special pipes and fittings at Dresden-Weixdorf specifically to satisfy this demand. All components, whether one-off or series production, are manufactured here with computer-controlled precision. Left and right pipe bending machines can master even complex pipe geometries. Machines equipped with a turret can make bend pipes to different radii in one working operation. This allows HANSA‑FLEX greater flexibility when making customised connections and shortens delivery times.

Special pipes and fittings from HANSA‑FLEX

You benefit from a number of services when HANSA‑FLEX manufactures special solutions.

Drawing on their many years of manufacturing experience in the field of bent pipelines and special fittings, our experts can realise the most complex special designs precisely to meet your requirements.

- Precision pipes in combination with hydraulic hoses

- All commercially available connection variants can be supplied

- Multiply bent pipes, adapters, collectors or manifolds

- Preassembled component groups for rapid installation

Additional services and products

Pipe-end processing by experienced experts

A perfect pipe needs an optimum connection. The HANSA‑FLEX pipe-end processing workshop produces safe, high-precision connections for every fluid technology application.

Safe systems with expansion joints from HANSA‑FLEX

Expansion joints accommodate vibrations and changes in length and angle to protect pipelines, machines and equipment from damage.

Securely connect hydraulic components with pipe fittings

Pipe fittings rely on a tight positive fit to create a safe connection, even when subjected to high working pressures, pressure peaks and vibrations.