Machine safety is playing an increasingly important role in both legislation and technical standards. For this reason the previously applicable DIN EN 201 standard from the year 2010 has been fundamentally revised and replaced by DIN EN ISO 20430. This has also resulted in changes regarding the safety requirements of hose assemblies.

The new DIN EN ISO 20430 standard requires that hose lines in hydraulics with pressures of more than 50 bar and in pneumatics with pressures of more than 10 bar must be secured against hazardous lashing around. This can be done either by cladding, additional fastening of the hose lines (by chains, cables or clamps) or a pressure test in accordance with DIN EN ISO 1402. Uncontrolled lashing around can occur if the hose tears out of its fitting or connection, or if the fitting is torn off at the connection point. This means that an interlock fitting is no longer a sufficient safeguard, as it only prevents the hose from tearing out of the fitting, but provides no protection against its being torn out at the connection point.

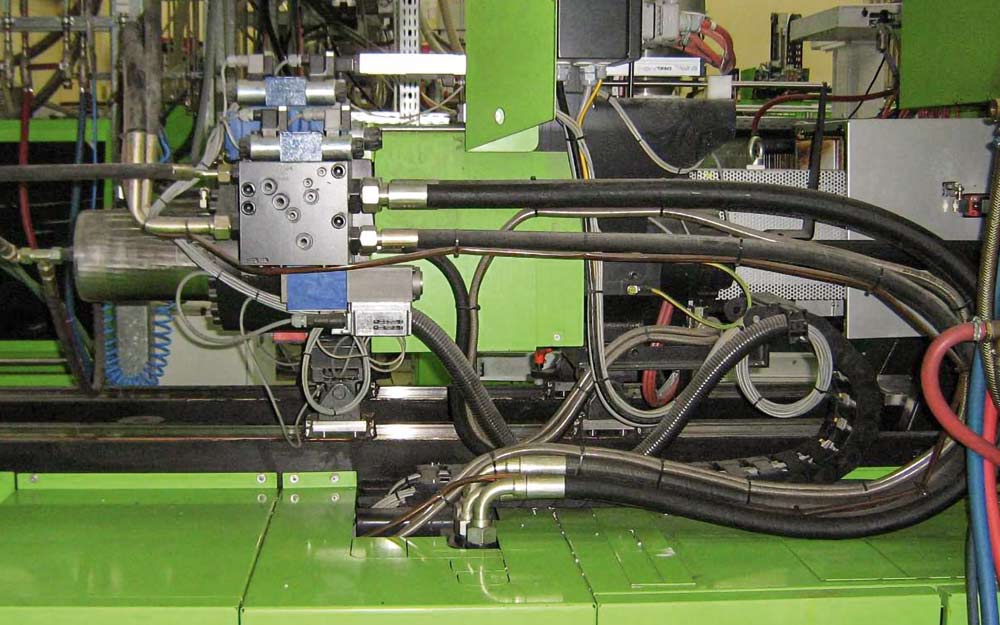

When using restraining cable devices (Fig. 1), it is important not to select just any old cables and attach them somehow or other. The manufacturer of such devices is obliged to develop, design and produce them in conformity with EC/EU directives. Furthermore, their functional suitability must also be tested. The CE marking confirms that this has been done. Designs produced in-house are not permitted. In order to guarantee the functionality of such a device, it requires correct design and assembly. The design is not only based on the maximum permissible operating pressure of the hose assembly, but also on the type of hose (weight), type of connection fitting, nominal diameter, bending radius etc.. Assembly must be carried out exclusively in accordance with the manufacturer’s fitting and installation instructions, because only then will functional safety and process reliability be ensured.

In practice, it is often the case that restraining cables are mounted under tension (Fig. 2). However, such mounting means that the hose can’t escape from the fitting and the energy can’t dissipate abruptly. The result is that the cable will break, and thus there is no protective function. The use of chains is not recommended because, especially in the case of lines that are subject to constant movement during operation, the chain links may separate from each other and thus their correct functioning is no longer ensured. A pressure test in accordance with DIN EN ISO 1402 means that the hose assemblies must be subjected to one-hundred percent testing. As a rule, this is done with twice the maximum permissible operating pressure for the hose assembly. A 3.1 inspection certificate must then be issued.

The duty to take such protective measures lies with both the manufacturer and operator of the machinery and with the hose assembly manufacturer. In the course of carrying out its risk assessment, the machine manufacturer must consider, within the defined machine limits, whether a protective measure against hose lines tearing free and lashing around is necessary. When procuring the hose lines it must be ensured that the supplier of the hose lines offers a tested hose-fitting combination. In addition, the correct design, e.g. pressure, temperature, medium, etc. must be taken into account. The operator of the machinery must carry out a risk assessment, taking into account and evaluating all potential hazards. If potential hazards emanating from the hose lines are diagnosed, the operator must take the necessary protective measures, e.g. against their tearing free and lashing around. It is also important for the hose assemblies to have a tested hose/fitting combination.

The manufacturer or service provider of hose assemblies should also always scrutinise the customer’s requirements. In other words, what exactly the hose line will be used for and whether a protective measure is needed to prevent it from tearing free and lashing around. At the Hydraulics Academy we recommend that in the case of freely accessible hose assemblies (Fig. 3) with an increased risk potential, a cover or enclosure or restraining cable device should be given priority over a pressure test. In the case of mobile service providers of hose lines, a pressure test is usually not possible because there is no test facility on the vehicles.

-

Daniel Werner

Trainer for line equipment and pneumatics at the International Hydraulics Academy (IHA)