OUR CUSTOMER MAGAZINE IN

SEPTEMBER

We are delighted to present issue #207 in September 2024! Can you spot what's hidden on the cover? Find out below.

Fit for the future

Axel Tammen, Head of Technology and Quality Assurance at HANSA‑FLEX, on the future of hydraulics.

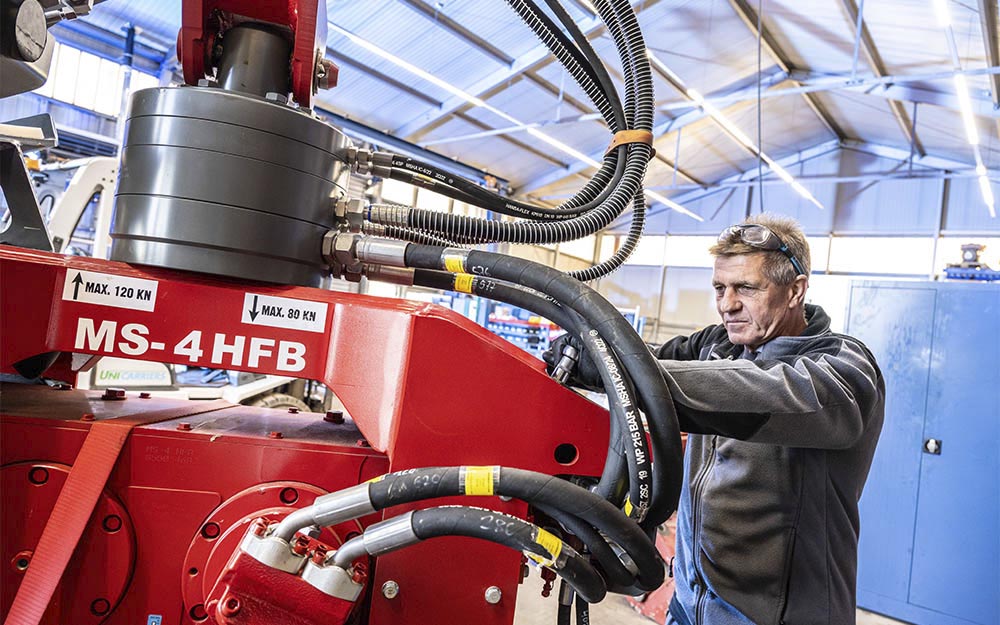

On an equal footing right from the start

A building site surrounded by water? terra infrastructure makes it possible, while HANSA‑FLEX provides the heavy-duty hydraulics required.

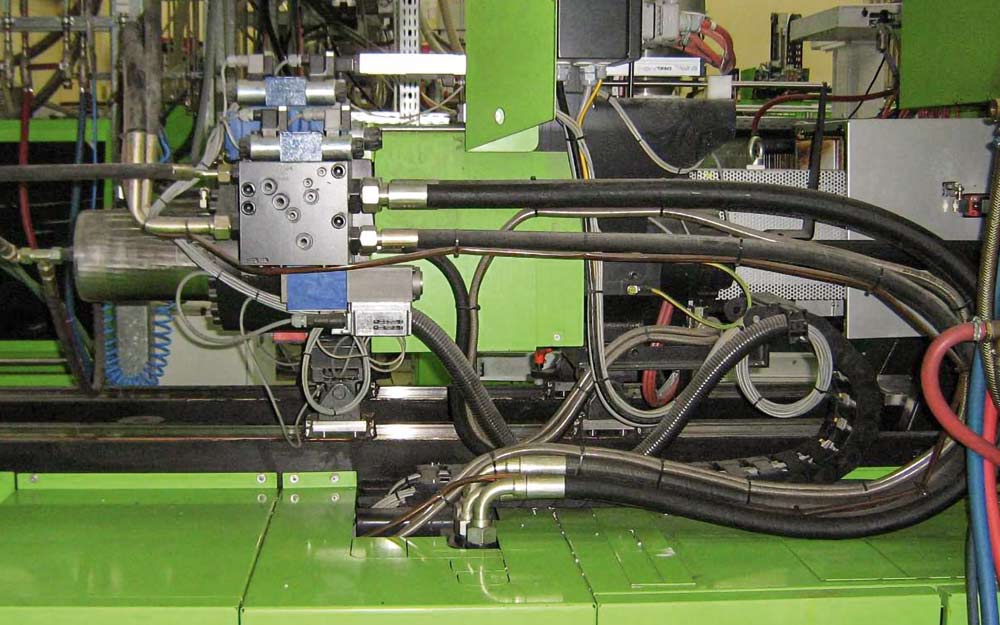

Technical expertise in hydraulics

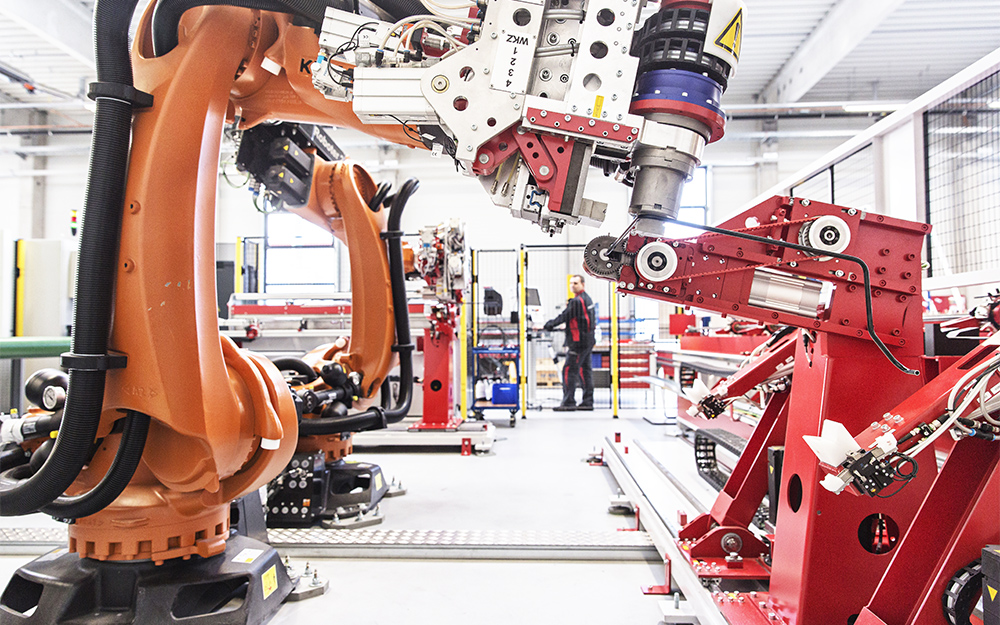

Have you recognised it?

The cover page of our current issue shows the robotic bending cell in the production area for pipes and special fittings. Steel pipes up to 18 x 1.5 mm can be bent in the bending cell with its 2 bending robots. The pipe sections are fed in via a chain conveyor up to 6 metres long, or via a step conveyor up to 2 metres long. The 2 robots in the bending cell can bend a pipe line synchronously (2 identical pipes at the same time), autonomously (2 different pipes at the same time) or working together.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/4/5/csm_DSC00907_08c8b343ad.jpg)

![[Translate to Englisch:]](/fileadmin/hansaflex/News_and_Events/Hydraulikpresse/2024/2024_September/web_2020_01_JG_EAB_HKO_001-0201_JON1208.jpg)