They are often installed out of sight, but their typical hum is unmistakable, and we encounter them every day in a wide variety of locations. Compact power packs are in action every time the tailboard of a lorry is lowered or raised, or when a mobile crane swivels its jib arm. Airport equipment, snow ploughs and forklift trucks also often owe their functionality to them. Most compact power packs essentially consist of a tank, a motor, a pump, a few valves and a control unit. That's all it takes to enable a whole host of different applications.

Operating principle and performance

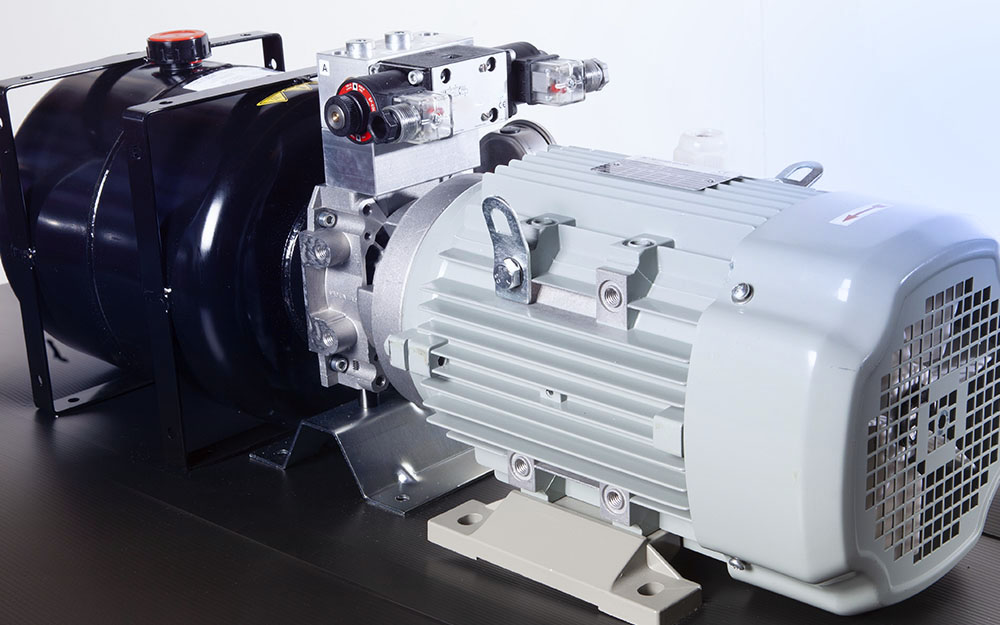

Just like standard hydraulic power packs, compact power packs provide hydraulic energy to operate all types of consumer units. They are comparatively small and are therefore mainly used in mobile applications. In compact power packs, the hydraulic pump is usually driven by an electric motor, hence the familiar humming sound. The pump generates hydraulic energy by building up pressure and volume flow. "Compact power packs usually have a fixed displacement pump that always delivers the same volume flow at a constant drive motor speed. The pressure then builds up depending on the load present on the consumer unit," explains Tino Zeuner, Product Manager Hydraulic Components at HANSA‑FLEX. In contrast to large power packs, the motor speed or output of compact power packs can't usually be regulated. In principle, the only options with compact power packs are whether or not they are under pressure. This simple provision of a volume flow and the corresponding pressure is suitable for simple and constant applications, such as lifting and lowering specific components or machine parts. Of course, their performance is limited by physics. The output of the drive motor and the delivery volume of the pump are the key parameters here. "Apart from size and controllability, this is the third main difference to large, stationary units, which can of course provide much more energy with larger motors and larger pumps," states Zeuner.

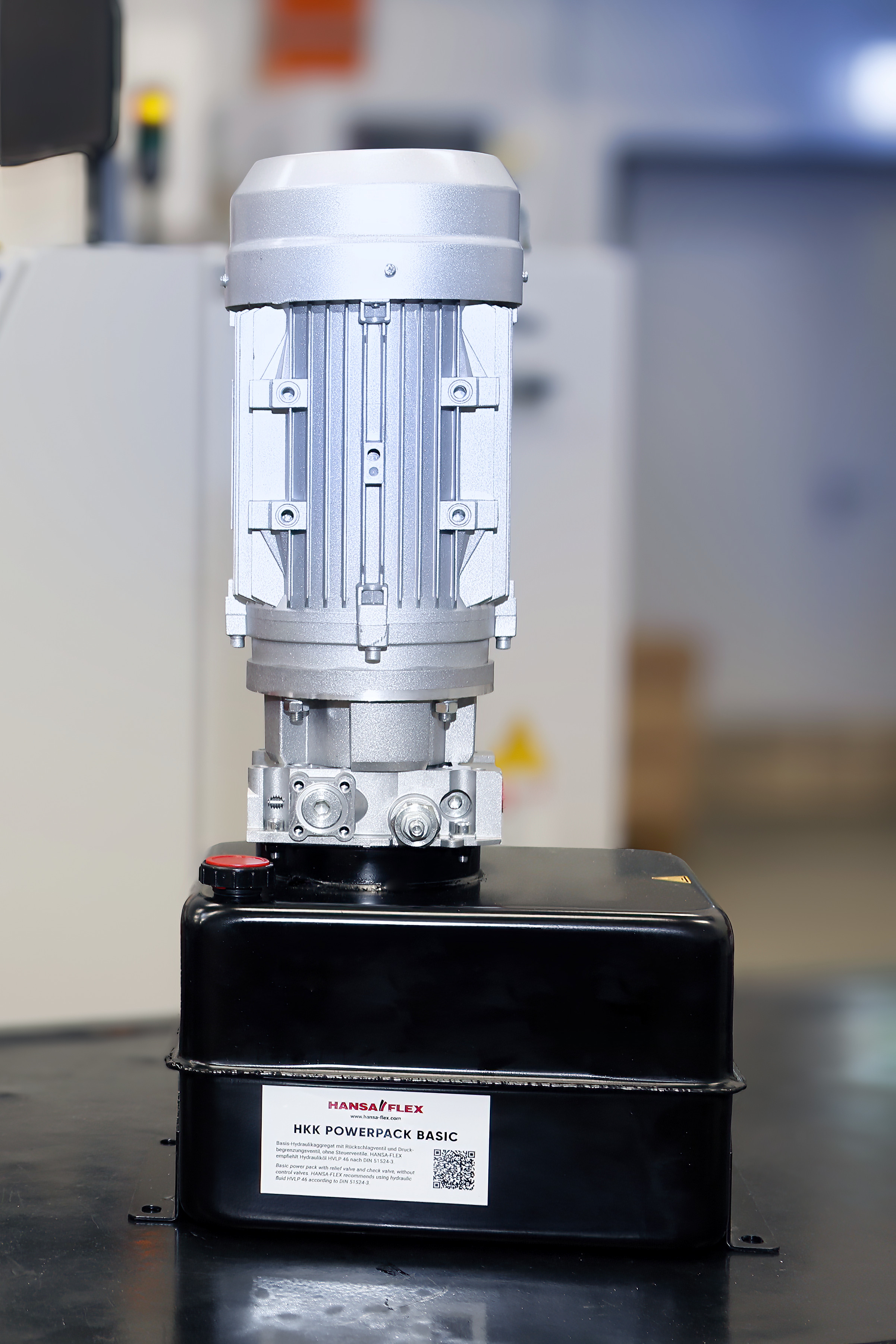

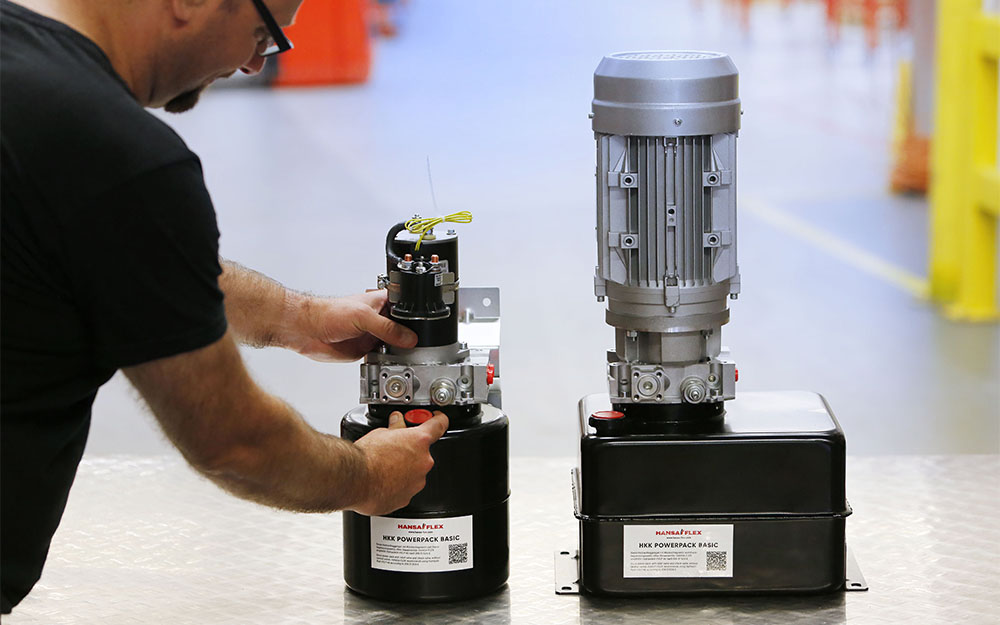

Focus on quality and customer requirements

HANSA‑FLEX offers compact power packs that are characterised by their high quality and durability. "Another important customer benefit is that our compact power packs are available from stock. If customers say they need the product tomorrow, they’ll get it tomorrow," promises Tino Zeuner. Initially, this is a basic unit purely for supplying pressure, and without valve equipment. However, the basic products can of course be configured according to customer requirements. Customers can either assemble the associated valve system themselves, or have it configured by the HANSA‑FLEX power pack construction service according to their individual requirements. Two different series, one with DC and one with AC motors, are available for ordering from the online shop or from a branch. HANSA‑FLEX has 5 types of each in its standard range. The HKK POWER DC BASIC DC power packs for mobile applications have a maximum output of 0.8 kW to 3 kW, with a tank volume of 5 or 8 litres. They generate a nominal pressure of 160 to 190 bar. The AC units for stationary applications have an output of 2.2 to 4 kW, and a tank volume of 12 or 30 litres. They provide a nominal pressure of 180 to 210 bar. In addition to these basic models, HANSA‑FLEX also has the configurable HKU 30-70 unit in its range. Customers can configure this model themselves in the online shop using the modular principle, so that the capacity, tank size and valves meet their exact requirements. For compact power packs, too, HANSA‑FLEX naturally offers a comprehensive service in the form of consulting, configuration, installation and commissioning as well as spare parts supply.