Hydraulics technician: a job where you learn by doing

Hydraulic systems are very complex to manage, and downtimes are usually very costly. At the same time, the potential for danger due to incorrect application and handling or to faulty installation should not be underestimated. For this reason, we at the HYDRAULICS ACADEMY are experiencing constantly increasing demand for the training of employees who work with hydraulic systems, equipment or machinery.

The reason for this is that many companies operate large and complex hydraulic systems. This is not to forget all the small and medium-sized companies that work with hydraulic systems in stationary and mobile applications. Hydraulics is indispensable in many industries, such as mechanical and plant engineering, construction, agricultural engineering, automotive and construction machinery, as well as in aviation.

To supply these industries with hydraulic products or components and to manufacture them in the appropriate way, companies need specialised personnel. Of course, the same applies later on for their operation and for the area of maintenance and servicing.

Hydraulics is to be found everywhere, but without really being noticed. Perhaps not surprisingly, there is no recognised apprenticeship that trains people for the profession of hydraulics technician. The apprenticeship for electricians or, nowadays, electronics technicians takes three and a half years. But what about hydraulics technicians?

During a training period of at least three years, electronics technicians learn to think in terms of systems, to work with circuit diagrams, to carry out measurements and to observe safety regulations. In the apprenticeship programmes for industrial mechanics, agricultural machinery specialists and automotive mechatronics technicians or toolmakers, hydraulics receives only scant attention in the teaching plans, both in theory and in practice. Currently, it is still the case that apprentices learn a great deal about pneumatics in the course of their training, but all they learn about oil hydraulics is that it “basically works the same way as pneumatics”. Nothing could be further from the truth!

To avoid the dangers presented by superficial knowledge (trial and error), industry has reacted by avoiding hydraulics wherever possible, developing plug and play systems that don’t require in-depth knowledge of hydraulics. This is feasible and possible to a certain extent, since the control functions are transferred to the electronics as much as possible. However, within the broad range of applications involving hydraulic systems, this is not always possible.

The following advantages make hydraulics an attractive and irreplaceable solution for a wide range of applications:

- favourable size and performance ratio

- powerful forces

- high dynamic levels, even with large masses and heavy loads

- perfect for executing linear movements

- huge forces can be controlled and precisely regulated

- more robust in general and in design

- little wear and tear

- overload-proof

- favourable cost-performance ratio

In many areas, such as construction machinery or press engineering, there are currently no alternatives.

What this means for companies

In order to effectively utilise the advantages of hydraulics, specialists also require the appropriate expertise, which is not taught to the required extent during vocational training. As a consequence, companies are largely responsible for training their hydraulic specialists themselves. However, this requires a great deal of personnel and time, and for many small and medium-sized companies this is not possible at all, both in terms of personnel and finance. On top of this, in hydraulics here are many safety issues that need to be addressed, arising from the Occupational Health and Safety Act, the Industrial Safety Ordinance, the Machinery Directive or Germany's Social Accident Insurance. After their training, electricians and electronics technicians are already familiar with the potential sources of danger, but is this also the case with hydraulics technicians?

Experience is a good teacher

Experience is a good teacher, but it can also come at a very high price if accidents happen and cause physical or environmental damage. Particularly in the area of maintenance and servicing, hydraulics is associated with unnecessary problems and doesn’t necessarily have the best reputation. The negative image of hydraulic drive systems could be due, among other things, to a lack of knowledge about how to work with this technology. This certainly does not apply to every company, but it does illustrate the general situation that we encounter in our seminars and discussions. To make matters worse, hydraulic systems are not as widespread as electrical installations and systems. To fully master the entire electrical-hydraulic system, we would need fluid mechatronics or hydraulic mechatronics technicians. The training programme would also have to cover proportional valve technology and regulated drive systems, including electronics and measurement technology, so that even in the event of a fault, the dispute between electricians/electronics technicians and hydraulics technicians becomes a thing of the past.

The IHA offers in-depth, coordinated hydraulic modules

For this purpose, THE IHA – INTERNATIONAL HYDRAULICS ACADEMY offers in-depth, coordinated hydraulic modules that have been developed from practical experience.

Hydraulic training equipment for practical training is often too expensive for many companies that provide apprenticeships. Furthermore, qualified trainers are needed who constantly work with the equipment and are always up to date on the latest developments. This is where the HYDRAULICS ACADEMY comes in with a practice-oriented seminar programme for assembly, maintenance and servicing operations. As an organisation that is independent of manufacturers, the IHA offers training without product presentations and marketing aspects, and thus concentrates on the essentials. This know-how not only provides a very good basis for manufacturers who wish to offer their own product-specific hydraulics training, but also for hydraulics service providers and their portfolio.

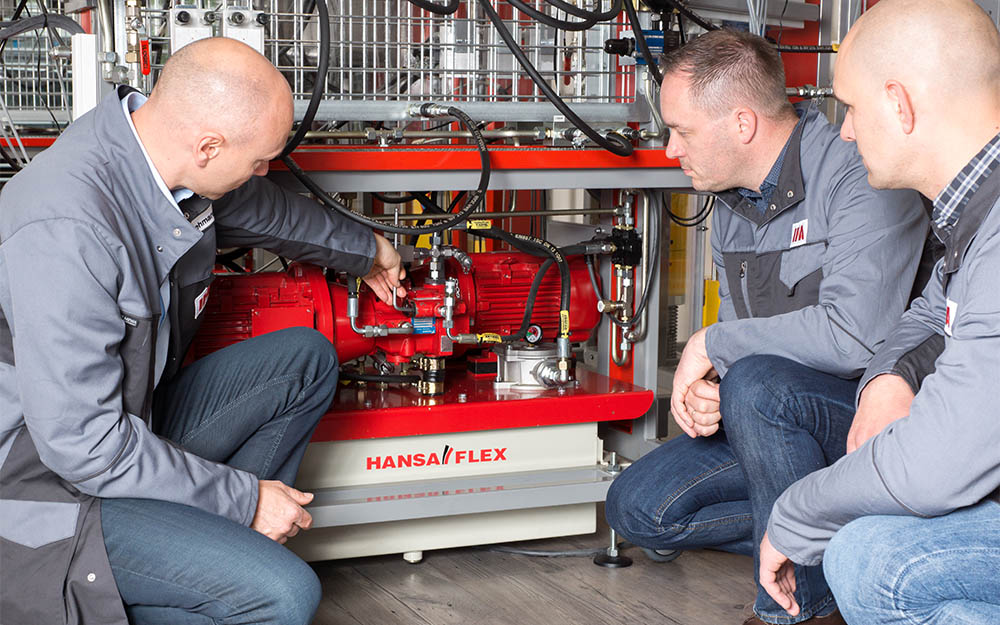

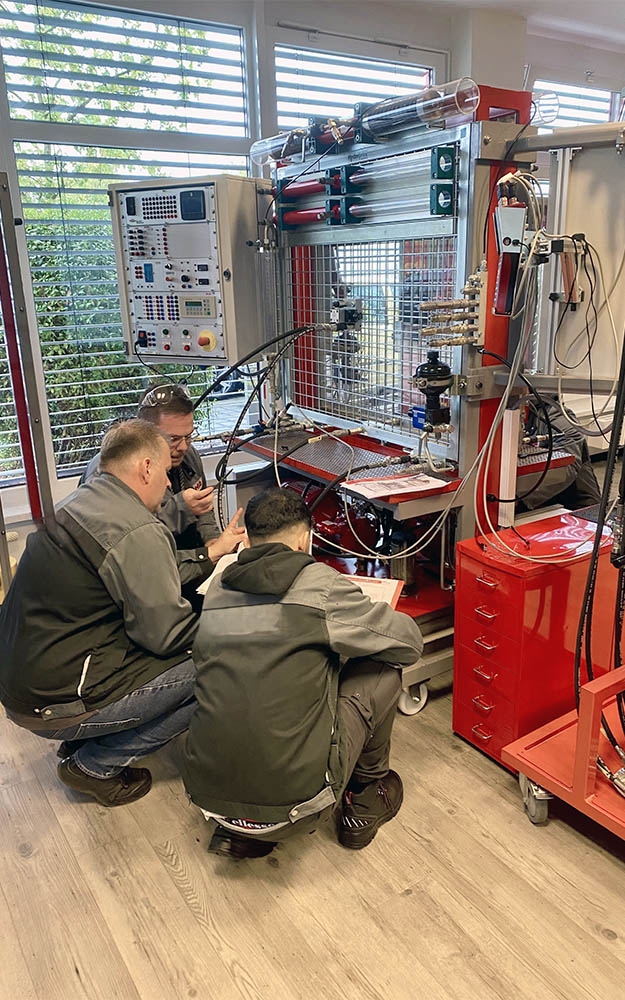

At all IHA hydraulics seminars, knowledge is also acquired through practical exercises in order to establish a connection to real-world applications. Topics are first explained theoretically by the trainer using animations and the latest presentation technology. The participants then develop a hydraulic circuit in which the discussed content is applied. Attention is also drawn to possible malfunctions and how to recognise them. This ensures a good practical focus and the seminars are correspondingly useful. Only two participants work together at the training benches.

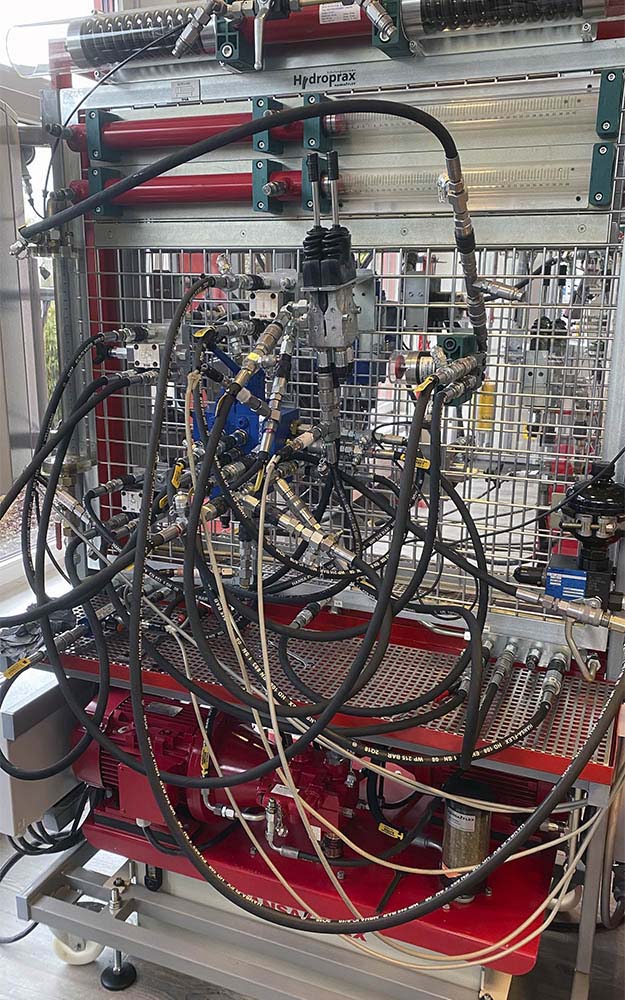

An example from advanced fluid technology

Since a cylinder without any load is not representative of the reality of hydraulic systems, load units with different load cases are used in the advanced exercises. These load units consist of a cylinder with an 80 kg suspended load, which first moves freely and then against a strong tension spring. The second load is a fast-acting winch with a 30 kg load. These loads can be used to demonstrate many hydraulic properties and to show how they can be properly controlled. It is also possible to try out things that should never be carried out on a real system. Each training workstation has its own pressure-controlled pump and genuine industrial components. During the seminars, the participants also carry out settings and measurements on the pumps themselves.

In order to avoid wasting time plugging in relay controls, electro-hydraulic exercises are performed using a PLC. The participants only need to plug in the sensors and actuators. This leaves the hydraulic circuit as the main focus. To avoid asking too much of the participants at the beginning, the exercises start with very simple tasks and then become more challenging.

The seminars build on each other to ensure successful training without overwhelming the participants.

Hydraulics 1 “The Basics” and Hydraulics 2 “The Advanced Seminar”

The content covers the basic function and design of the fundamental components of hydraulics. Each topic is explored in depth with the aid of a large number of practical exercises to aid understanding.

Conclusion

With the appropriate, in-depth hydraulics expertise, designers can develop energy-efficient and environmentally friendly systems that also meet sustainability criteria. Applications engineers, for their part, acquire problem-solving skills in hydraulic operation. Development of preventive maintenance and servicing concepts through in-depth knowledge of hydraulics offers greater and more reliable machine availability.

Acquiring expertise in hydraulics provides a competitive edge, brings innovation and secures jobs.

For this purpose, the HYDRAULICS ACADEMY offers an additional qualification within a short period of time, and with real substance. With one week of instruction per month, in only nine months we prepare participants for the “Hydraulics specialist” advanced training qualification, which is recognised by the Chamber of Trades. After passing the final Chamber of Trades examination, you will have taken another step up the career ladder. This represents our contribution to the profession of hydraulics technician.

-

Ulrich Hielscher

Managing Partner, Trainer for line technology and hydraulic oils at the International Hydraulics Academy