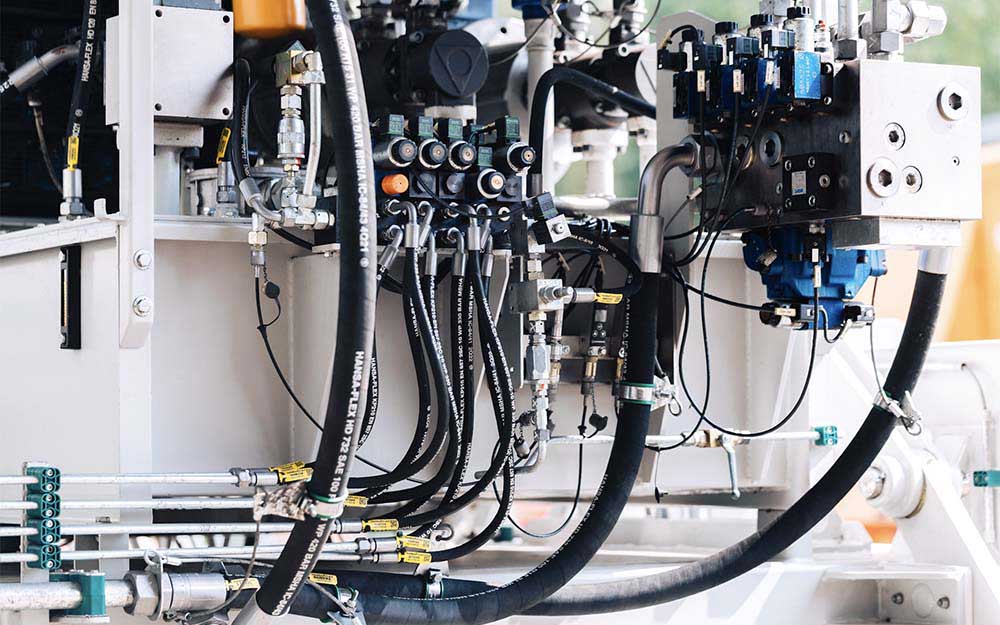

When replacing hydraulic hose lines, it is essential to adhere to the instructions of the machinery or system manufacturer. Close attention must be paid to the technical specifications provided by the manufacturer to ensure safe and reliable operation. The maximum load, here the maximum permissible pressure that the hydraulic hose line can withstand, must not be exceeded under normal operating conditions. Some systems also have special requirements that need to be taken into account. If the nominal pressures given for the hose and the fitting differ, then the lower value always determines the working pressure of the complete hose line.

- Working pressure

- Volumetric flow

- Medium

- Temperature

- Environmental factors

- Bending and impulse loads

- The safety requirements to be observed

5 key points for choosing the right hose, fittings & accessories

1. Fittings

In making the right choice of fittings, it is preferable to choose fittings that fulfil widely accepted international product standards such as DIN, EN, ISO or SAE. Before this choice can be made, it must be decided whether to use a hose fitting with an elastomer sealing element (e.g. DKOL, DKOS, ORFS) or one with a purely metallic form of seal (e.g. JIC, DKR). A hose fitting with an elastomer sealing element should always be preferable. However, for certain applications, such as where the seals are incompatible with the medium in use or where high temperatures prevail, the fallback choice is often a metallic form of seal.

In addition, the geometry of the connection needs to be considered. For example, if the installation situation is such that the bending radius of the hose line would be too small, an elbow fitting should be chosen to avoid kinking the hose line. Moreover, the natural curvature of the hose line should be taken into account when choosing the offset angle of the fitting.

Finally, the environmental conditions are an important factor in the choice of components. If, for example, there is a risk of corrosion by salt water, the recommended choice is stainless steel fittings.

Further information about connection geometries:

Technical information Connection technology Pipe fittings (PDF)

2. Hose

As with fittings, the chosen hose should be one that complies with widely accepted standards such as DIN, EN, ISO or SAE. Depending on the application (pressure and temperature loads), various hose materials can be used such as elastomer or thermoplastic hoses with pressure carriers made from steel or textile braid.

It is essential that the choice of hose is matched to the expected conditions of use. Therefore, for example, if the conditions involve high impulse loading, then the right choice would be HANSA‑FLEX series KP100S, KP200S or HD700LL hose, which have been tested to withstand up to 1,000,000 impulse cycles among other things on our test bench.

The nominal diameter of a hose line should be selected such that overloading of the hose line from excessively high fluid flow velocities is avoided.

3. Fitting type

In addition to no-skive crimp ferrules, in which the sleeve is pushed over the unpeeled hose and then crimped, in order to speed up the assembly of hose lines, hose fittings with skive crimp ferrules can be used for braided hoses.

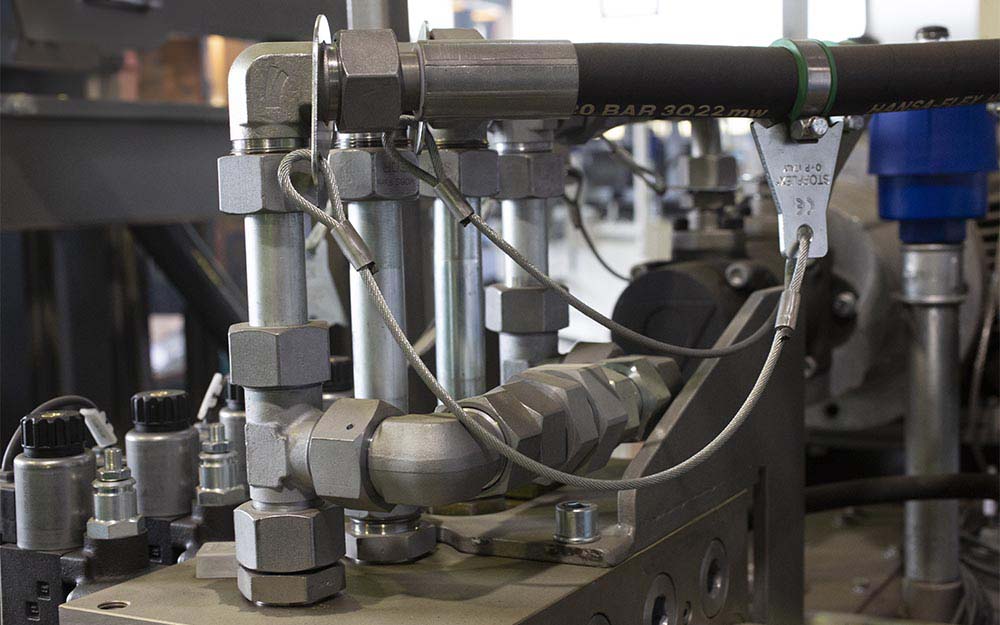

To ensure a safe connection between hose and fitting under extreme loads and high pressures of up to 500 bar, interlock fittings can be used as a system solution with pull-out protection. The inner and outer layers of the hose are peeled to allow the crimp nipple to achieve a highly effective positive fit with the hose and the ferrule.

Good to know: As a rule, when you order preassembled hose lines from HANSA‑FLEX, we have already made the choice of compatible fitting types for you.

Hydraulic hose lines should ideally be purchased only from a specialist workshop, where they are manufactured professionally and in conformance with the standards. In this way, all the components are optimised for use with one another and will function reliably. If, however, hose lines are assembled by the user, it is particularly important to ensure that the hose and fittings are a perfect match. This means that the dimensions, the shape and, above all, the pressure rating of the components must be chosen to suit one another. Here it is absolutely essential to follow the guidelines provided by the manufacturers of the hose and fittings in order to ensure safety and proper functioning.

4. Accessories for protecting personnel

The safety of personnel when operating machinery and equipment is of fundamental importance when designing a hydraulic system. Various international standards, regulations and guidelines stipulate protective measures in certain situations, especially in the field of hydraulics. The risks include hose line whiplash and the escape of fluids such as hydraulic oil or other media under high pressure.

Whiplash

In order to minimise the risk of whiplash from a defective hose line, protective measures to suit the risk should be introduced.

In these situations, we recommend the use of hose retention systems.

Escape of hydraulic fluids under high pressure:

To mitigate this risk, we recommend the use of TGF ISO protective hose.

Proper installation must always be ensured when using the above protective measures.

For example, in the case of hose restraints / hose retention systems, attention must be paid to using the correct lengths of cable and their proper attachment to the machinery components and hose lines. With a protective hose, it is essential to choose the appropriate internal diameter, which must be at least 30% larger than the outside diameter of the hose line used.

Caution: Improper installation degrades the protective effect and can lead to serious injury of personnel.

5. Accessories for hose protection

Hose lines may well be exposed to extreme loads. Solutions to protect against chafing, kinking and heat can be a worthwhile addition to prevent damage.

The selection of appropriate hose accessories must be made to suit the hose lines used and the conditions of use, such as temperature and environmental factors.

HANSA‑FLEX offers a comprehensive product portfolio for the protection of hose lines:

- Chafing and kink protection made from various materials

- Heat protection up to 260 °C using silicate, silicone or glass fibre

- Condensation protection

Mexico

Mexico