Digital order processing and simple ordering: To increase efficiency, companies are looking at existing processes. Which analogue process steps can be digitised and which manual errors can be avoided by using technology? Scan-to-order offers the solution to both challenges in the procurement process.

What does Scan-to-Order mean?

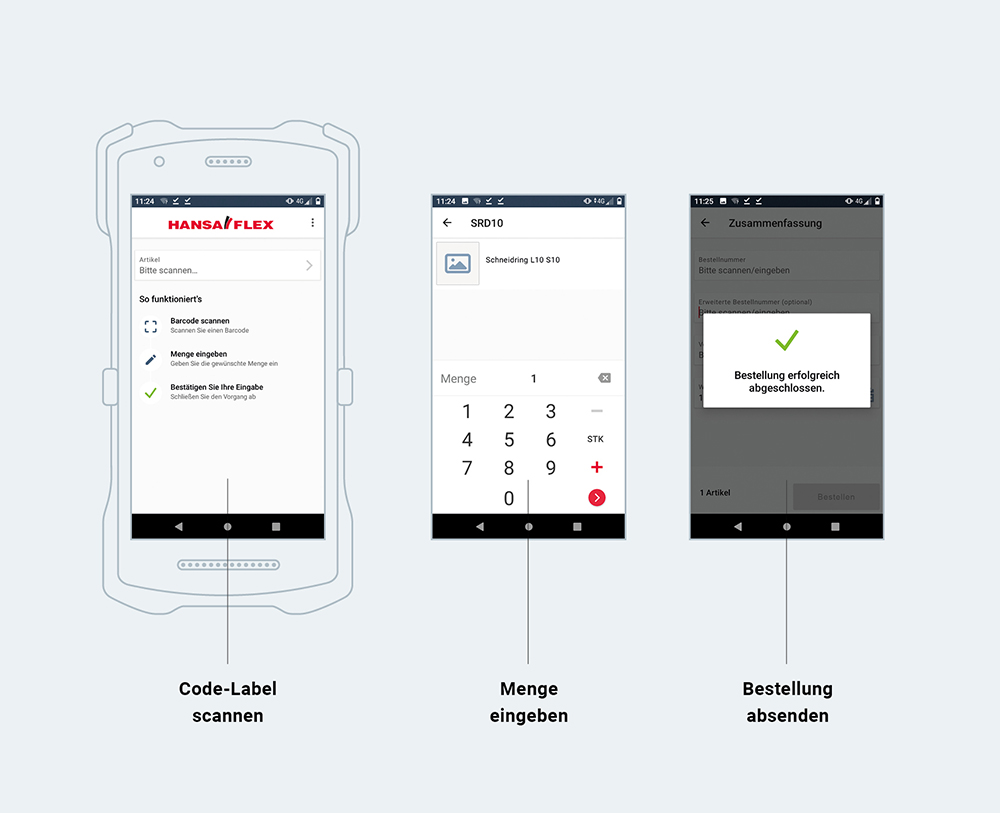

Scan-to-order is a digital ordering process in which orders are triggered directly in the company by using scanners. In this process, goods containers or shelf bins are labelled with QR or barcodes. The current purchase requirement is recorded by scanning the codes and the order is triggered and transmitted digitally after confirmation. The required items are recorded, ordered and then delivered. If desired, you can install a manual order release as a control mechanism in the process. This means that recorded requirements are approved by the purchasing department before the actual order is placed.

The process is more efficient and more resistant to errors, as orders are initiated or triggered directly at the point of need by scanning. This saves time and simplifies warehouse management.

How does Scan-to-Order work?

1. Suitable labelling with scannable codes, such as barcodes and QR codes

To record product-specific information such as product name, packaging unit (PU) and customer material information (CMI), labelling such as QR or barcodes are used. With scan-to-order, the labels are attached directly to the shelving system or container and scanned for ordering. With HANSA‑FLEX Scan-to-Order, you can choose between barcode or QR code. You can continue to use your own product names when switching to HANSA‑FLEX Scan-to-Order. You do not have to switch to HANSA‑FLEX product names because our system references your material number.

2. Connection to the merchandise management system

As soon as a barcode or QR code is scanned, the Scan-to-Order app transmits the information directly to the HANSA‑FLEX ERP system. On request, you will receive an order receipt confirmation as a CSV file with order information that you can use to create your own ERP document. This automated process reduces manual errors and improves efficiency in warehouse management.

3. Required apps and devices

The mobile app plays a key role in the HANSA‑FLEX Scan-to-Order system. It is installed on Zebra laser scanners and enables barcodes or QR codes to be scanned. The mobile app communicates directly with the ERP system and can transmit orders in real time. We start by equipping you with suitable scanners and, if required, suitable shelf containers and hanging fixtures. We set up both the hardware and software for you.

4. Working without an internet connection

The HANSA‑FLEX Scan-to-Order system offers offline functionality so that work can also be carried out without an internet connection. The app saves scanned data locally and transmits the data to the ERP system as soon as an internet connection is available again. This ensures reliable order processing, even in remote or network-weak areas.

5. Data security

Data security is crucial when company data such as order information is transmitted. With the HANSA‑FLEX Scan-to-Order system, data transmission between the app and the ERP system is encrypted.

What are the perks of digital repeat orders with scan-to-order?

Order correctly with certainty:

The digital recording of required items prevents manual errors that occur when manually entering article numbers, for example. You can order from the entire HANSA‑FLEX range with scan-to-order. Whether hydraulic and pneumatic components such as couplings, valves and adapters, consumables such as oils, sprays and adhesives or even customised hose lines for your company.

Controlled order quantity:

You have the option of implementing a release step from your central purchasing department in the process, allowing you to control the quantity and type of items that are ordered. This allows you to adjust the order quantity to your warehouse capacities and ensure that only as many goods are ordered as is economically and logistically necessary.

Efficient utilisation of storage space:

Have hydraulic components and consumables resupplied at regular intervals instead of keeping them in high stock levels. With Scan-to-Order, you can quickly and easily keep track of your stock and utilise your storage space as efficiently as possible.

Exactly the products you need:

You can control not only the delivery quantity, but also what you order. Both standard products and customised hose assemblies can be reordered via Scan-to-Order.

How is Scan-to-Order implemented? In 4 simple steps:

1. Needs analysis on site

Our technical advisors work with you to determine your regular hydraulic and pneumatic requirements. Together, we optimise your parts lists and design your spare parts and warehouse logistics.

2. Quotation preparation

Whether just with an app and scanner or as part of a complete package including services such as shelf assembly, goods clearance and training: You will receive a non-binding offer from us that is precisely tailored to your needs.

3. Provision of goods and accessories

When you place an order, we print your labels, configure the scanners and put together the container and shelving systems you require.

4. Training

On request, we can train your employees and ensure that everyone in the team can work with Scan-to-Order without any problems.

Mexico

Mexico