A sought-after one-stop partner

Efficient material logistics

Added value through service

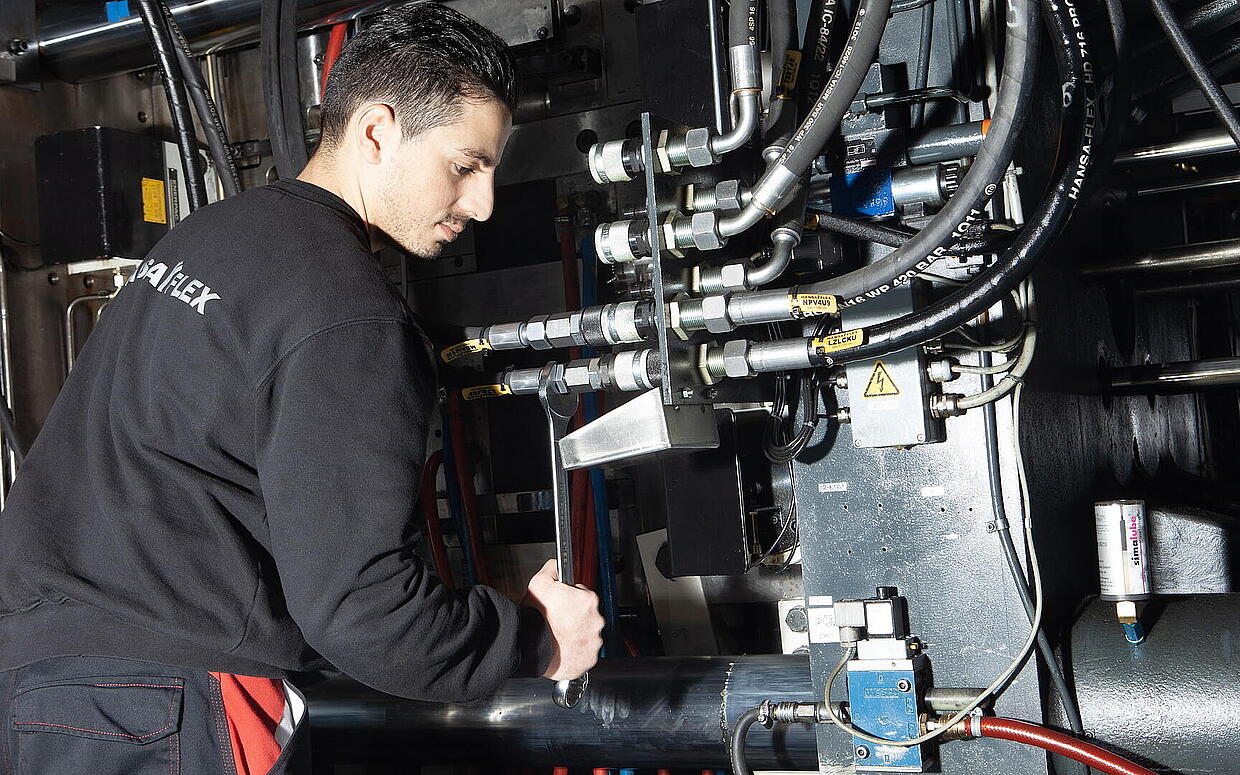

This is something that BSH particularly values: “The fluid service and industrial service divisions play a major role in safeguarding system availability in our production facilities”, comments Geis. For example, the fluid service division ensures effective oil servicing in order to reliably prevent excessive component wear and thus disruptions and even production downtime. The hydraulic specialists in the industrial service division are responsible for inspecting, maintaining and servicing machines on site in the plant. HANSA‑FLEX can even provide optimisation services and completely refurbish production systems.

Mexico

Mexico