Why should you use HANSA‑FLEX adsorber filters?

2. The use of adsorber filters eliminates the need for air conditioning to prevent the build-up of condensation in operating environments.

3. Refillable series are designed in such a way that only those components that have actually reached the end of their product life need to be replaced and recycled. Produktlebenszyklus erreicht haben.

Adsorber filters are suitable for many areas of application

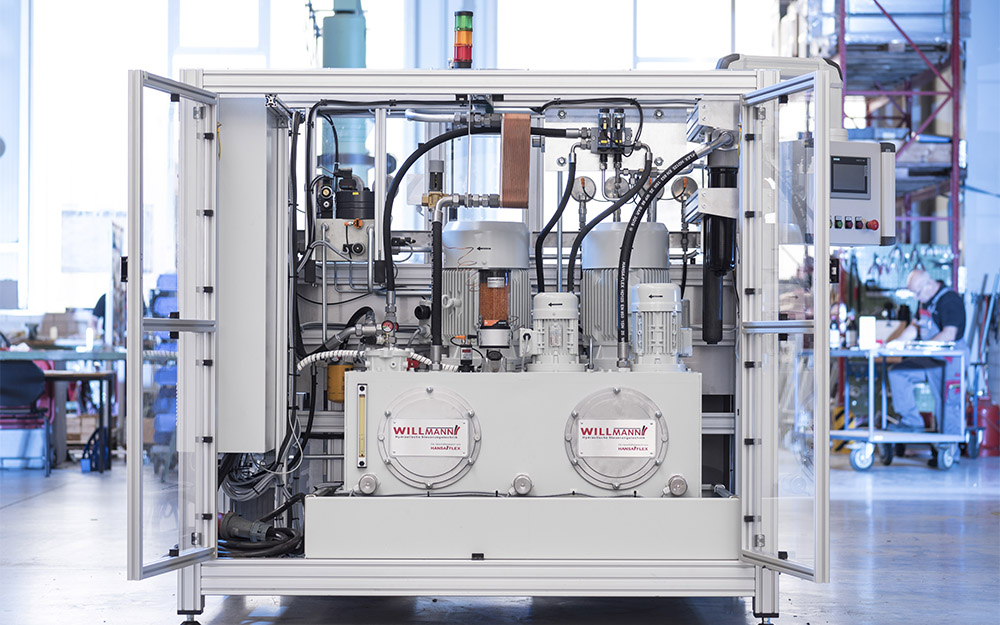

Adsorber filters for hydraulic power packs and transmission systems prevent corrosion and protect the hydraulic oil from contamination by water and dirt particles, thus increasing the service life of the system and the oil.

Tank ventilation dryers protect hygroscopic substances in storage tanks from contact with humidity, and prevent moisture damage to the tank itself. They ensure that the quality of the stored media is maintained and protect hygroscopic substances such as isocyanate, oils and biological fuels in drums and IBCs in particular from coming into contact with moisture.

Adsorber filters protect transformers from hydrolysis of the cellulose paper in the transformer, and thus from a reduction in the degree of polymerisation by effectively drying and filtering the intake of moist air.

Contacts in switch cabinets, corrosion-prone housings and moisture-sensitive goods are protected by adsorbers against contact with moisture in the air.

Adsorber filters protect biodegradable and water-sensitive bio oils in hydraulic tanks from contamination by water. Mobile machines can consequently be operated with more environmentally friendly bio oils without any difficulty.

Inline adsorbers are able to dry process air at up to 10 bar (145 psi) and filter out pollutants. This significantly increases the service life of a system, as both corrosion and maintenance work are eliminated.

How do HANSA‑FLEX adsorber filters work?

How adsorber filters work in practice

2. If hydraulic oil is removed from the tank, the oil level drops and the pressure is equalised by the incoming air. The adsorber captures moisture from this incoming air. The relative humidity of the air is then only 2 % RH.

3. When the hydraulic oil is pumped back into the tank, the oil level rises and the pressure is equalised by the escaping dry air.

4. As the air inside the system always remains dry, there is no condensation in the hydraulic unit, even if the ambient air falls below the dew point, and full performance is maintained.

Do you have any questions about adsorber filters? Simply get in touch with us! We'll be happy to help and advise you.