HANSA‑FLEX Belgium has been working with Fisheye since 2023. So far, two spectacular projects have been completed together. In the process, both partners have got to know and appreciate each other.

"If you can dream it, we can build it" is the slogan under which Fisheye from Wetteren in Belgium offers one-stop-shop solutions for extraordinary exhibits. The multifaceted production company combines creativity, craftsmanship and technology, thinks out of the box and enables its customers to create unforgettable experiences. Customers include the Tomorrowland Festival and the media company Studio 100, among others. In Fisheye projects, virtual and physical space often mix. Cutting-edge software meets rustic wooden design, while filigree lighting installations set the scene for exhibits weighing several tonnes. To ensure that the transition between physical spaces and media is as seamless as possible, the hydraulics must also integrate harmoniously into the overall concept. For two of their projects to date, the creative experts have enlisted the support of HANSA‑FLEX & LIS hydraulics to provide solutions for highly complex hydraulic requirements.

Ensuring realistic waves

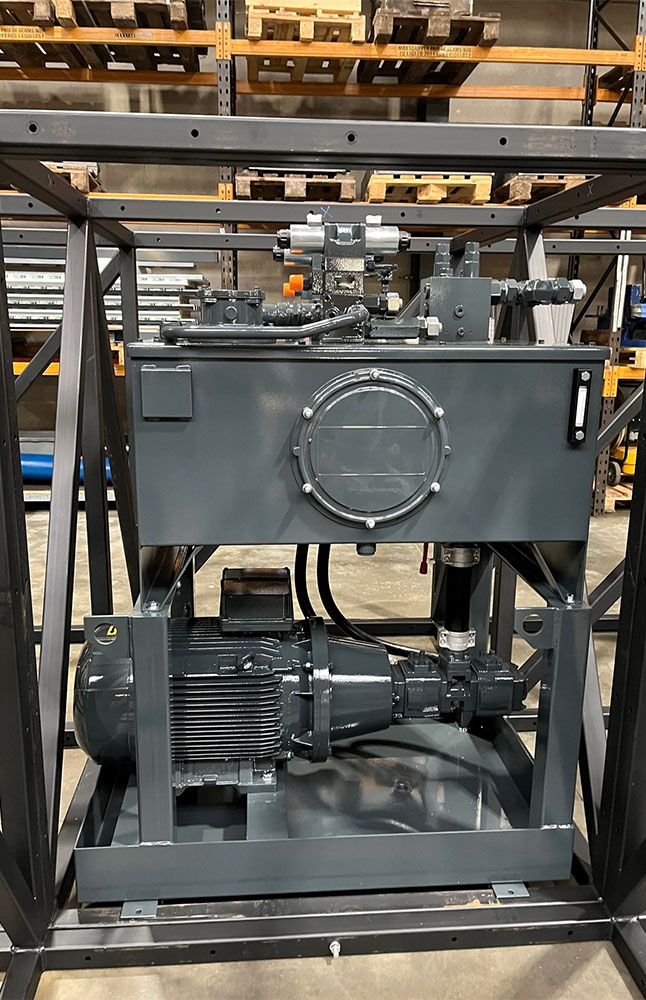

On the one side there are Fisheye’s creativity experts, and on the other HANSA‑FLEX with its extensive hydraulics know-how as practical experts. "We have very different approaches, so it was important for me that we should get to know each other in a pilot project to see if the collaboration would work," says Stijn Slabbinck, CEO of Fisheye. The pilot project was part of the production of the musical Red Star Line, which premiered in Puurs in March 2023. The central stage set element is a replica of the luxury liner Belgenland, which travelled between Antwerp and New York from 1923. In order to offer the audience as authentic an experience as possible, the bow of the ship had to be movable. With its engineering, pipes, hoses, power units and cylinders, HANSA‑FLEX & LIS hydraulics managed to ensure that the bow moved as if through mighty waves while the actors braved the storms. In the process the hydraulics had to enable smooth movements via remote control, and avoid any jerkiness. "The engineering and materials have to be top-notch for such creative projects, from conceptualisation, design and drafting to production and technical development," emphasises Jan Delvaux, Sales & Branch Manager, HANSA‑FLEX Belgium. Finding the optimum balance between material requirements, weight distribution and hydraulic performance proved to be extremely tricky. However, thanks to their combined wealth of experience and close collaboration, the experts were able to develop the solution on time and within budget. Fisheye CEO Stijn Slabbinck is highly satisfied with the partnership on the pilot project: "Things clicked immediately with HANSA‑FLEX. Right from the start, we sensed that they were just as committed to the project as we were."

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/hansaflex/References/Maschinen-_und_Anlagenbau/Fisheye/009_FisheyeTomorrowland_KH_2024_03-.jpg)

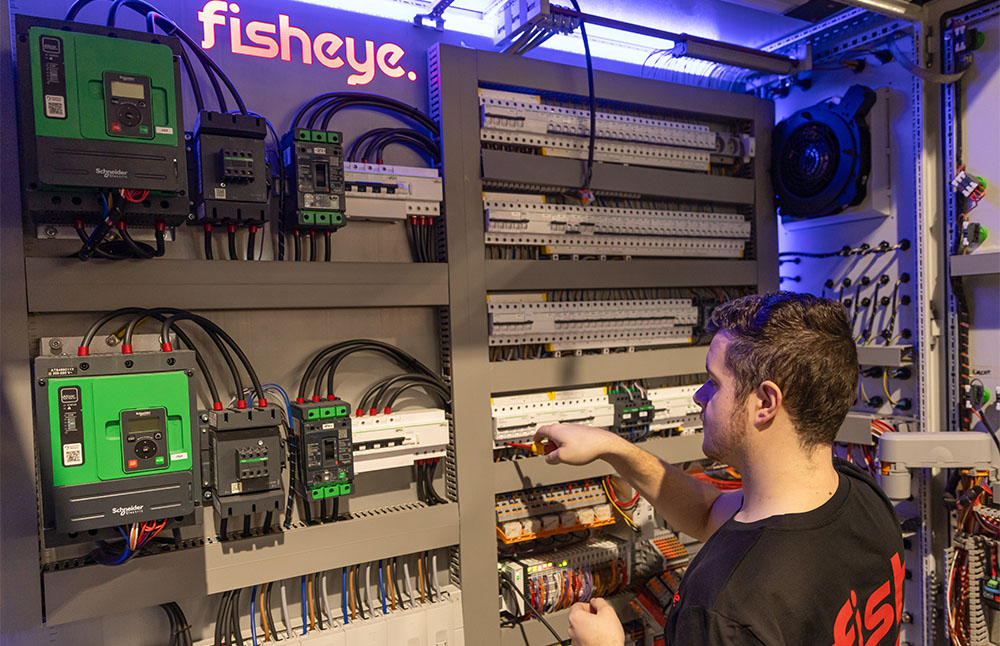

Hydraulic finesse for the dragon lady

A very special joint project was the reworking of the Rose Garden stage installation designed by the Tomorrowland team and built by Fisheye. The main character is Rosie, a dragon lady with large eyes and long eyelashes. The omnidirectional movements of the dragon's eyes, mouth, gills and head have to be perfectly coordinated. "The movements need to be much more delicate than those of a machine, so it’s very difficult to keep the hydraulics under control," explains Joos Knapen, hydraulics specialist at the HANSA‑FLEX subsidiary LIS hydraulics. Special proportioning valves were therefore used to bring Rosie to life. Fisheye developed the valve control software together with experienced HANSA‑FLEX programmers. Rosie is now up to date and Stijn Slabbinck is extremely pleased: "For me, it's not just about the budget, but also about good cooperation and mutual understanding. We had that with HANSA‑FLEX from day one, so I’ll be happy to work with them again on hydraulics-controlled projects at any time." Jan Delvaux is also full of praise for the cooperation between HANSA‑FLEX and the colleagues at the new subsidiary LIS hydraulics: "Our colleagues are great and I look forward to many more projects with them and our customer Fisheye."

Mexico

Mexico

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/hansaflex/References/Maschinen-_und_Anlagenbau/Fisheye/005_FisheyeTomorrowland_KH_2024_03-.jpg)